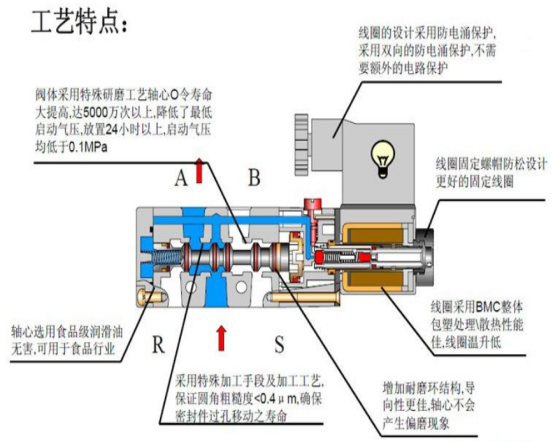

Pneumatic solenoid valve has a closed chamber, in different positions open through the hole, each hole of the pneumatic solenoid valve leads to a different trachea, the middle of the chamber is a valve, two sides are two electromagnets, which side of the magnet coil energized valve body will be attracted to which side;

Pneumatic solenoid valve by controlling the movement of the valve body to stop or leak different exhaust holes, and the air inlet is often open, high pressure gas will enter a different exhaust pipe, and then through the pneumatic solenoid valve pressure to promote the cylinder piston, so by controlling the solenoid valve electromagnet current to control the mechanical movement of the solenoid valve.

We say the pneumatic solenoid valve working position (solenoid valve open or closed), in fact, refers to the location of the pneumatic solenoid valve spool.

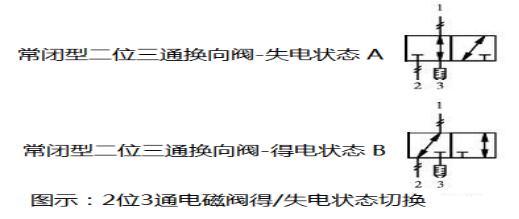

The spool is in position A when the coil is not energized, and is in position B when the coil is energized. When the pneumatic solenoid valve spool in a different position, the valve body on the interface to play or connected or closed. For example, two-position solenoid valve refers to the solenoid valve spool has two different working positions (open or closed), for the pneumatic solenoid valve is the solenoid valve charged state and power loss state; The valve it controls is the opening and closing of the valve. Two way, three way solenoid valve, refers to the pneumatic solenoid valve body has two, three orifice. Two-position two-way solenoid valve with one in one out of the two channels, is the most common pneumatic solenoid valve; Two three-way solenoid valve, is one into two out of the three channels, the two out of the channel are the corresponding connection is normally open and normally closed. Similarly, tee, tee, tee, and tee also refer to the number of fluid channels on the valve body.

As one of the commonly used accessories of pneumatic valves, pneumatic solenoid valve plays a very important role, mainly used for the air source reversal of pneumatic valves.

1.Two-position five-way solenoid valve is used with double acting pneumatic valves.

2.Two-position three-way solenoid valves are used in conjunction with single acting pneumatic valves.

The explosion-proof coil can be selected according to the working condition to achieve explosion-proof effect. It can operate normally at the ambient temperature of -20~70℃. Pneumatic reversing solenoid valve according to the actual situation and valve needs, can choose mount type and tube type installation.

1.Fitted with NAMUR standard and VDI/VDE3845 double hole, its medium is filtered through 50 micron, lubricated or unlubricated compressed air. The air source interface is G1/4 tube, and the electrical interface is PG9 connection.

2.According to international standards, explosion-proof solenoid valve contains NAMUR plate connection, pipe connection, 2/3, 2/5 four functions, can directly control single and double acting pneumatic actuator, and equipped with a safe and reliable manual device, is a real multifunctional solenoid valve.

3.Because of its unique gas path structure, explosion-proof electromagnetic valve body on all breathing holes are communicated with the exhaust hole, valve body surface no breathing holes and atmosphere, can effectively prevent the outside liquid, dust and impurities into the valve body, especially suitable for use in outdoor or dust pollution serious working environment.

Notice to quotation: Optional accessories: solenoid valve, limit switch, two couplings

Please try to provide detailed parameters about each standard pneumatic ball valve, to facilitate our technical personnel for your accurate selection.