First.Product introduction

Nitrogen sealing device is mainly used at the top of the storage tank to maintain the micro positive pressure of the storage tank, isolate the contact between materials and the outside world, reduce volatilization and waste of materials, and protect the safety of the storage tank.

Nitrogen seal valve without external energy, using the modulated medium's own energy as power source. Pressure stabilizer that automatically controls the valve medium flow to keep the valve pressure constant. It has been widely used in continuous gas production and transportation, city gas and metallurgy, petroleum, chemical industry and other production sectors.

The valve features: high control accuracy, comparable to the ordinary type of direct operation type pressure regulating valve about twice. Adjust the pressure difference ratio is large (such as 0.8MPa before the valve, 0.001MPa after the valve) especially suitable for micro-pressure gas control. The pressure setting is realized on the controller, so it is convenient, fast, labor-saving and can be set continuously in running state.

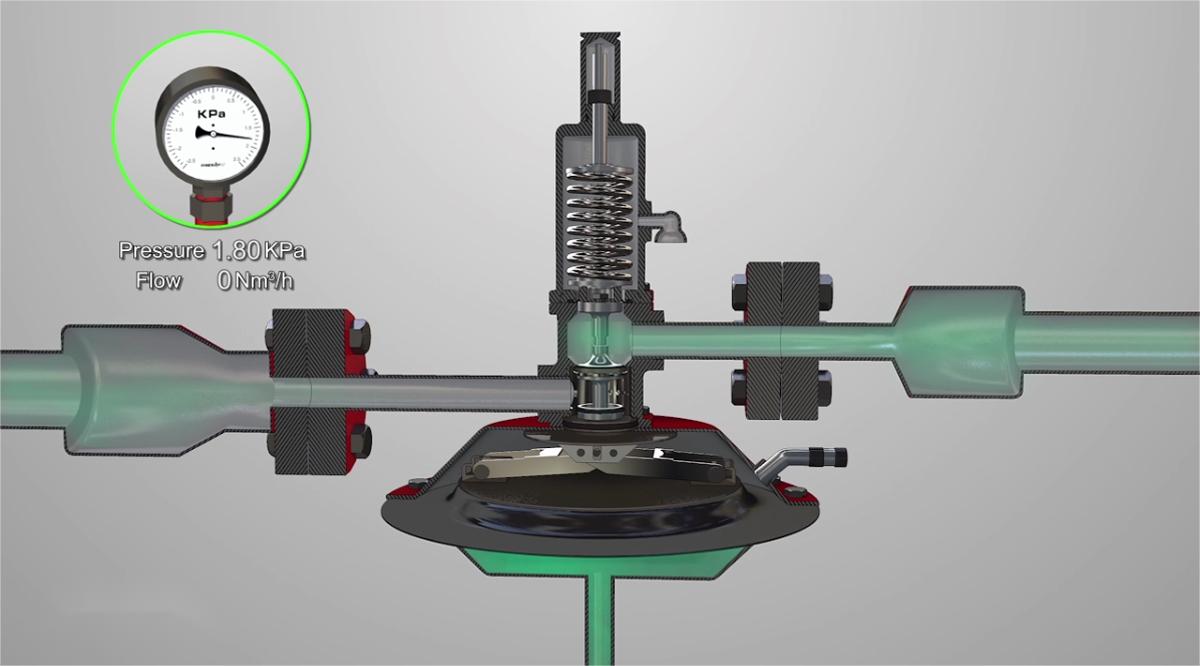

(1)When the nitrogen seal valve is closed, the piston of the main valve is in a sealed chamber. When the tank pressure is equal to or greater than the set pressure, the diaphragm is pushed upward, and the air pilot valve moves upward under the action of the spring, pressing the seal ring on the air pilot valve tightly on the seat, closing the control gas inlet. At the same time, the pressure in the special spool chamber increases and approaches the pressure of the nitrogen main pipe. This pressure is transmitted from the special spool chamber to the main spool chamber through an internal channel. The piston of the main valve is under the action of nitrogen main pipe pressure. Because the upper and lower gas pressure of the main valve spool is balanced, the main valve spool is closed tightly under the action of dead weight and spring.

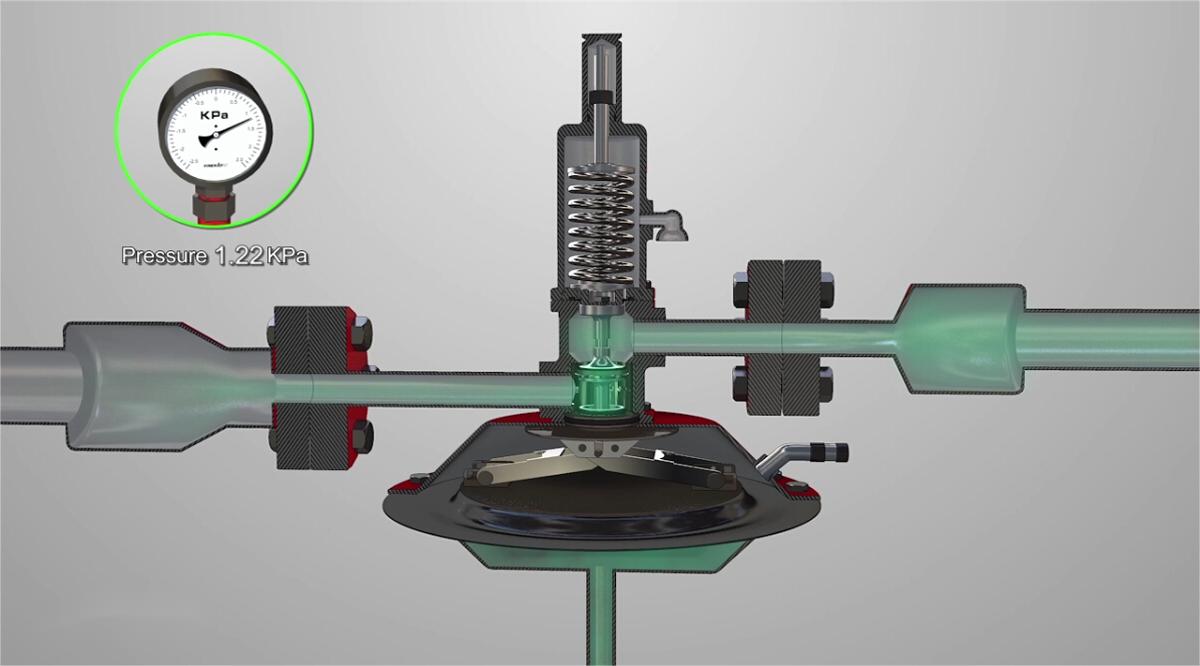

(2)When the nitrogen seal valve is opened, when the tank pressure is slightly lower than the set pressure, the diaphragm moves down because of the induced pressure drop, pushing the air pilot valve to open, and nitrogen enters the tank through the orifice plate and the outlet of the air pilot valve, so that the pressure inside the tank increases. At the same time, the pressure of the special spool chamber of the air pilot valve drops, and nitrogen enters the main valve spool chamber from the special spool chamber through the internal channel. Because the piston area of the main valve spool is greater than the area of the main valve seat hole, and has the spring's elasticity and the weight of the main valve, when the tank pressure is slightly below the set point, the pressure reduction in the special spool chamber and the main valve spool chamber is small, the main valve remains closed, and nitrogen enters the tank only through the air pilot valve.

3.1Nitrogen seal device is composed of control valve, actuator, pressure spring, conductor, pulse tube and other components. It is mainly used to keep the pressure of the protective gas (usually nitrogen) at the top of the container constant, so as to avoid direct contact between the materials in the container and the air, prevent volatilization and oxidation of the materials, and ensure the safety of the container. Especially suitable for all kinds of large storage tank air seal protection system. The product has the characteristics of energy saving, sensitive action, reliable operation, convenient operation and maintenance. Widely used in petroleum, chemical and other industries.

3.2The nitrogen supply device introduces the medium at the pressure point on the top of the tank into the detection mechanism through the pressure guide tube. The medium generates a force on the detection element that is balanced with the spring and the preload force. When the tank pressure is reduced to lower than the nitrogen supply device pressure set point, the balance is destroyed, so that the conductor spool, open, the valve before the gas through the pressure reducing valve, throttle valve, into the main valve actuator upper and lower membrane chamber, open the main valve spool, to fill the tank with nitrogen; When the tank pressure rises to the nitrogen supply device pressure set point, due to the preset spring force, close the conductor spool, due to the spring in the main valve actuator, close the main valve, stop the nitrogen supply.

3.3Nitrogen discharge device, the device adopts an internal feedback structure, the medium directly through the valve cover into the detection mechanism, the medium on the detection element to produce a force balanced with the preset spring preload force. When the pressure in the tank rises to higher than the pressure setting point of the nitrogen discharge device, the balance is destroyed, so that the spool moves upward, the valve is opened, and the nitrogen is discharged to the outside world; When the tank pressure drops to the pressure set point of the nitrogen discharge device, the valve is closed due to the preset spring force.

1、Valve body parameters: caliber, working pressure, valve body material, using medium, connection form and other parameters

2、Actuator: actuator form, control mode, control signal (4-20MA), mode of action (gas-open gas-close type)

3、Optional accessories: solenoid valve, limit switch, two couplings

Please try to provide details about the parameters of each standard electric valve, to facilitate our company's technical personnel for your accurate selection.