First, product overview:

FL641F4 pneumatic fluorine lined discharge valve is mainly used for the bottom discharge, discharge, sampling and no dead zone shutdown operation of reactor, storage tank and other containers. The bottom flange of the valve is welded to the bottom of the tank and other containers, thus eliminating the usual residual phenomenon of process media at the outlet. Discharge valve according to the needs of the actual situation, the bottom structure design is flat bottom type, the valve body is V-shaped, and provides two kinds of lifting and falling working mode disc. The valve body cavity with erosion resistance, corrosion resistance of the seal ring, in the opening of the valve moment, can protect the valve body from being washed by the medium, corrosion, and special treatment of the seal ring, so that it has high wear resistance, corrosion resistance function, to ensure the reliability of the seal, and can prevent scarring. At the same time take short stroke valve disc design.

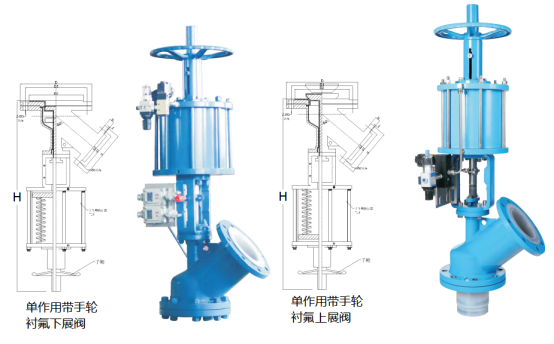

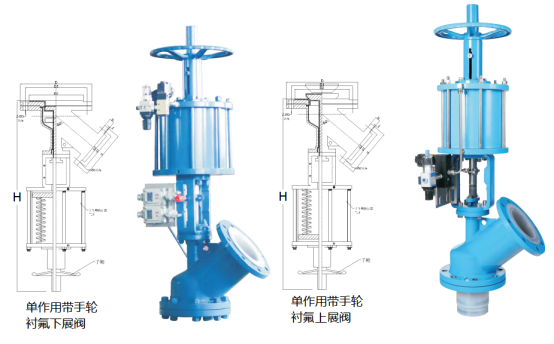

Second, the difference between the upper and lower opening type discharging valve:

1. Discharge valve is mainly used for discharging materials at the bottom of storage tank, reaction kettle and other containers. The valve is connected with the equipment by flange or butt welding and is located at the bottom, which eliminates the residual phenomenon of process medium usually at the outlet of the container.

2. According to the needs of the actual situation, it can be divided into three structural forms: up-spread type, down-spread type and plunger type; The upspread type is used for discharge of the reaction kettle with agitator (except frame anchor type); The downward expansion type and the plunger type are used for the reaction kettle discharge of the frame anchor agitator.

Third, applicable medium and temperature:

(1) Various corrosive media can be used (WCB+F46 material temperature using -20℃-120℃).

(2) It is strictly prohibited to use media such as particles, pulp, (stainless steel +F46 can use temperature -60℃-120℃).

(3) Strictly prohibit the use of fluorine-containing ionic liquids (such as HF, etc.) can use strong alkali and strong acid (temperature less than 120℃).

| Product name: | Pneumatic fluorine lined up/down expansion discharge valve | Applicable medium: | Liquid materials, other materials, etc |

| Nominal diameter: | DN25~DN250 | Structural form: | Up-spread and down-spread |

| Nominal pressure: | 1.6MPa~2.5MPa~4.0MPa | Connection mode: | flange |

| Applicable temperature: | -29ºC~+425ºC | Driving mode: | Manual, pneumatic, electric |

| Body/lining material: | Cast steel+F46/PFA

Stainless steel+F46/PFA | Manufacturing standard: | GB, German DIN, the United States API、ANSI |

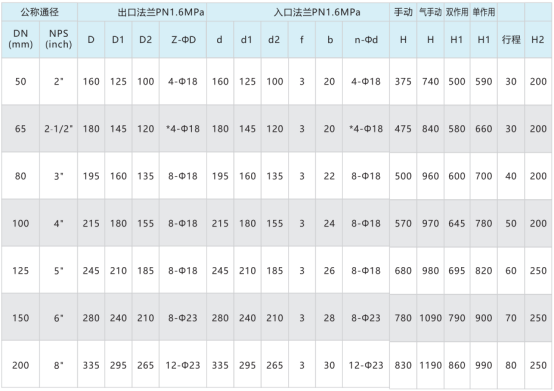

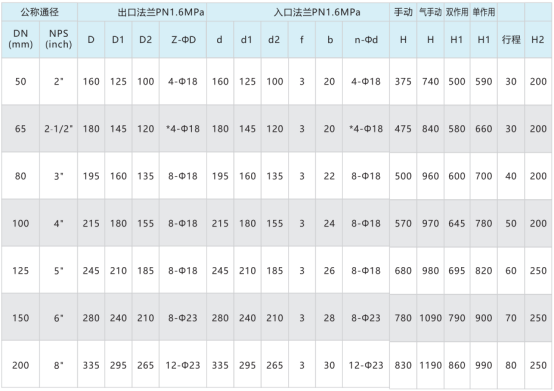

Standard specification

1. Design and manufacturing standard according to GB/T12235-2007

2. The standard of structure length is according to the enterprise standard

3. Flange connection according to JB/T79-94, GB/T9113 HG20592-2009, etc

4. Test and inspection according to GB/T13927-2008

Note: The above size is for reference only, the specific size is based on physical objects.

Notice to quotation:

1, valve body parameters: caliber, working pressure, valve body material, using medium, connection form and other parameters

2, actuator: actuator form, control mode, control signal (4-20MA), mode of action (gas-open gas-close type)

3, optional accessories: solenoid valve, limit switch, two couplings

Please try to provide detailed parameters about each standard pneumatic ball valve, to facilitate our technical personnel for your accurate selection.