The working principle of the upper and lower expansion discharge valve: the principle of the valve stem to push the disc up and down, so as to achieve the purpose of opening and closing. When the hand wheel turns along, the stem goes up and the valve closes. When the hand wheel reverses, the stem drops and the valve closes. The upspread type is used for discharge of the reaction kettle with agitator (except frame anchor type); The downward expansion type and the plunger type are used for the reaction kettle discharge of the frame anchor agitator. The sealing surface is made of scour and corrosion-resistant materials, and is specially treated to make the surface hardness reach HRC48 ~ 52. It has the function of high wear resistance and corrosion resistance, which ensures the sealing reliability of the valve. Widely used in chemical, petroleum, metallurgy, pharmaceutical, dye, food processing and other industries.

| Air source working pressure | 0.4~0.7MPa |

| Ambient temperature and medium temperature | 5~60℃ |

| Electromagnetic control signal current | 4~20mA |

| Product name: | Pneumatic up/down expansion discharge valve | Applicable medium: | Granular materials, crystalline particles, other materials, etc |

| Nominal diameter: | DN25~DN250 | Structural form: | Up-spread and down-spread |

| Nominal pressure: | 1.6MPa~2.5MPa~4.0MPa | Connection mode: | flange |

| Applicable temperature: | -29ºC~+425ºC | Driving mode: | Manual, pneumatic, electric |

| Valve body material: | Cast steel, stainless steel | Manufacturing standard: | GB, German DIN, American API, ANSI |

Standard specification

Material of main parts

| Part name | ZG1Cr18Ni9Ti series | ZG00Cr18Ni10 series | ZG1Cr18Ni12MO 2 Ti series | ZG00Cr17Ni14MO 2 series | WCB series |

| Body/bonnet | ZG1Cr18Ni9Ti | ZG00Cr18Ni10 | ZG1Cr18Ni12MO 2 Ti | ZG00Cr17Ni14MO 2 | WCB |

| Valve stem | ZG1Cr18Ni9Ti | ZG00Cr18Ni10 | ZG1Cr18Ni12MO 2 Ti | ZG00Cr17Ni14MO 2 | WCB |

| disc | ZG1Cr18Ni9Ti | ZG00Cr18Ni10 | ZG1Cr18Ni12MO 2 Ti | ZG00Cr17Ni14MO 2 | WCB |

| gasket | 304+PTFE | 304L+PTFE | 316+PTFE | 316L+PTFE | graphite+304 |

| stud | 1Cr17Ni2 | 1Cr17Ni2 | 1Cr17Ni2 | 1Cr17Ni2 | 35CrMoA |

| nut | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 45 |

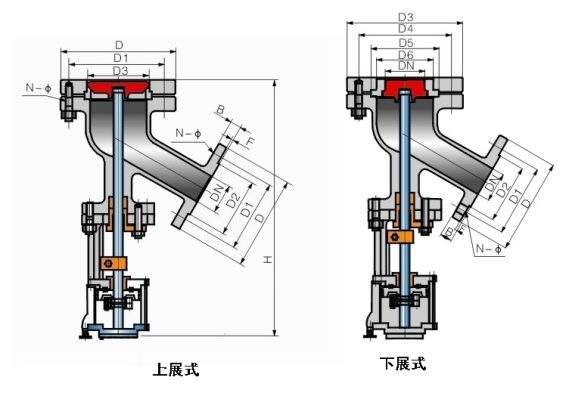

Outline structure drawing

Main dimensions (upspread)

| DN | d | D | D1 | D2 | D3 | D4 | D5 | D6 |

| 25 | 25 | 115 | 85 | 65 | 115 | 85 | 60 | 40 |

| 32 | 32 | 135 | 100 | 78 | 135 | 100 | 65 | 45 |

| 40 | 40 | 145 | 110 | 85 | 145 | 110 | 80 | 60 |

| 50 | 50 | 160 | 125 | 100 | 160 | 125 | 85 | 70 |

| 65 | 65 | 180 | 145 | 120 | 180 | 145 | 125 | 85 |

| 80 | 80 | 195 | 160 | 135 | 195 | 160 | 135 | 95 |

| 100 | 100 | 215 | 180 | 155 | 215 | 180 | 160 | 130 |

| 125 | 125 | 245 | 210 | 185 | 245 | 210 | 180 | 140 |

| 150 | 150 | 280 | 240 | 210 | 280 | 240 | 185 | 165 |

| 200 | 200 | 335 | 295 | 265 | 335 | 295 | 255 | 230 |

| 250 | 250 | 405 | 355 | 320 | 460 | 410 | 350 | 240 |

| DN | d | D | D1 | D2 | D3 | D4 | D5 | D6 |

| 25 | 25 | 115 | 85 | 65 | 135 | 100 | 75 | 55 |

| 32 | 32 | 135 | 100 | 78 | 145 | 110 | 80 | 57 |

| 40 | 40 | 145 | 110 | 85 | 160 | 125 | 100 | 65 |

| 50 | 50 | 160 | 125 | 100 | 180 | 145 | 125 | 70 |

| 65 | 65 | 180 | 145 | 120 | 195 | 160 | 135 | 90 |

| 80 | 80 | 195 | 160 | 135 | 215 | 180 | 155 | 130 |

| 100 | 100 | 215 | 180 | 155 | 245 | 210 | 195 | 135 |

| 125 | 125 | 245 | 210 | 185 | 280 | 240 | 180 | 145 |

| 150 | 150 | 280 | 240 | 210 | 335 | 295 | 215 | 185 |

| 200 | 200 | 335 | 295 | 265 | 405 | 355 | 300 | 220 |

| 250 | 250 | 405 | 355 | 320 | 460 | 410 | 350 | 240 |