First, product overview

Three-way ball valve generally adopts two seat structure, can also use four valve empty structure according to user requirements. Widely used in chemical, petrochemical, petroleum, paper, mining, electric power, liquefied gas, food, pharmaceutical, water supply and drainage, municipal, mechanical equipment supporting, electronic industry, urban construction and other fields.

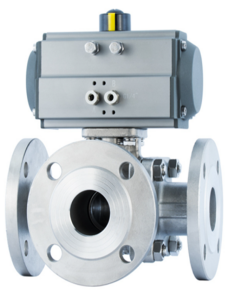

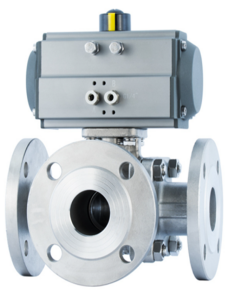

Pneumatic three-way ball valve L type Q644F and T type Q645F.

L-type three-way ball valve is suitable for switching the flow direction of the medium, so that the two channels are connected perpendicular to each other.

T - tee ball valve is suitable for medium shunt, confluence or flow direction switching. A T-channel can connect three channels to each other or two of them.

Second, pneumatic three-way ball valve characteristics

1 fluid resistance is small, full diameter ball valve basically no flow resistance.

2. Simple structure, small volume, light weight.

3. Tight and reliable. It has two sealing surface, and the sealing surface material of the ball valve is widely used in various plastics, good sealing, can achieve complete sealing. It has also been widely used in its air systems.

4. Easy to operate, open and close quickly, from fully open to fully closed as long as the rotation of 90 degrees, easy to remote control.

5. After convenient repair, ball valve structure is simple, sealing ring is generally active, disassembly and replacement are more convenient. 6. When fully open or fully closed, the sealing surface of the rotary body and the valve seat is high with the medium, and the medium will not cause the erosion of the sealing surface of the valve.

7. Wide range of application, small diameter to a few millimeters, large to a few meters, from high to high pressure can be applied. 8. Ball valves can be used in media with suspended solid particles because of their wipeability during opening and closing.

| Part name | Material name |

| Valve body | WCB | 304(CF8) | 316(CF8M) | 316L(CF3M) |

| sphere | 2Cr13+Nitriding treatment | 304 | 316 | 316L |

| Valve stem | 2Cr13 | 304 | 316 | 316L |

| Sealing ring | Polytetrafluoroethylene (PTFE), reinforced polytetrafluoroethylene (PPL), para polystyrene, flexible graphite |

| Applicable medium | Water, gas, steam, oil, etc | Corrosive media such as nitric acid | Acetic acid and other corrosive media | Urea and other corrosive media |

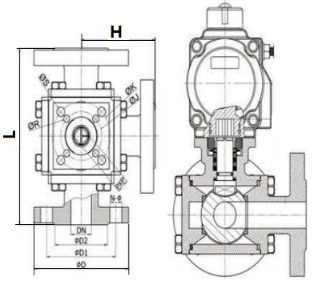

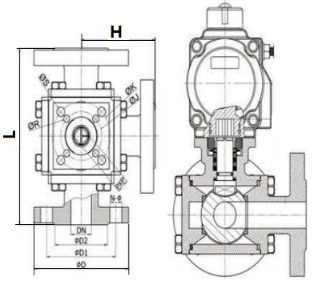

Third, the main connection size:

| Nominal pressure PN | Nominal diameter DN | size(nrn) |

| L | H | D | D1 | D2 | b | N*d |

| 1.6MPa | 15 | 150 | 75 | 95 | 65 | 46 | 12 | 4-Ф14 |

| 20 | 160 | 80 | 105 | 75 | 56 | 14 | 4-Ф14 |

| 25 | 180 | 90 | 115 | 85 | 65 | 14 | 4-Ф14 |

| 32 | 200 | 100 | 140 | 100 | 76 | 16 | 4-Ф18 |

| 40 | 220 | 110 | 150 | 110 | 84 | 16 | 4-Ф18 |

| 50 | 240 | 120 | 165 | 125 | 99 | 17 | 4-Ф18 |

| 65 | 260 | 130 | 185 | 145 | 118 | 18 | 8-Ф18 |

| 80 | 280 | 140 | 200 | 160 | 132 | 18 | 8-Ф18 |

| 100 | 320 | 160 | 220 | 180 | 156 | 20 | 8-Ф18 |

| 125 | 380 | 190 | 250 | 210 | 184 | 20 | 8-Ф18 |

| 150 | 440 | 220 | 285 | 240 | 211 | 22 | 8-Ф22 |

| 200 | 580 | 290 | 340 | 295 | 265 | 24 | 12-Ф22 |

| 250 | 670 | 335 | 405 | 355 | 320 | 26 | 12-Ф26 |

| 300 | 760 | 380 | 460 | 410 | 375 | 29 | 12-Ф26 |