Product introduction

※ Product name:Three-way ball valve lined with fluorine

※ Product model:Q44F46-16C/Q45F46(L/T型)

※ Product specification:DN25-300

※ Shell material: carbon steel、304

※ Lining material:FEP(F46)、PFA

First, Overview

Three-way lined fluorine ball valve has a compact structure, beautiful appearance, good sealing performance, it can realize the medium flow in the pipeline switch, can also make the two vertical channels connected or closed, the four seat seal has a beautiful shape, compact and reasonable structure, it can not only realize the medium flow switch, but also make the three channels connected to each other, now can also close any channel, Make the other two channels connected, flexible control pipeline medium confluence or diversion, widely used in acid, alkali and other corrosive media and toxic, volatile, permeable gas, liquid media control.

Second, advantages

1. Ball valve with fluorine plastic lining layer, with high chemical stability, suitable for any strong corrosive chemical media.

2. The all-pass floating ball valve structure is adopted to close the element leakage within the whole pressure range, which is convenient for the pipeline system to sweep the line in the ball and pipeline maintenance.

Third, product introduction

1. The fluid resistance is small, the lining ball valve wall is smooth, and the flow passage is smooth. It is the least fluid resistance of all the valves.

2. Quick and convenient switch.

3. The lining material is lined on the inner wall of the valve shell by special molding process, which can resist the corrosion of strong acid and alkali medium. The lining sphere is combined with PTFE seat for good sealing and zero leakage. The ball needs to be rotated 90 degrees to complete the opening and closing actions.

4. Pneumatic, electric, hydraulic and other driving devices can be configured to achieve remote control and automatic operation.

5 ball and valve stem integration, eliminate the rotation Angle difference, put an end to the pressure change caused by the risk of valve stem out of the body, to ensure the safety and reliability of use.

Product parameter

First, design standards Design standard | HG/T 3704,GB/T 12237 | API 60 |

Structural length | HG/T 3704,GB/T 12221 | ASMEB16.10 |

Flange size | HG/T 20592,GB/T 9119 | ASME B16.5, JIS B2220 |

Inspection and test | G8/T 13927,J8/T 9092 | API 598 |

Nominal, pressure(MPa) | | 1.0 | 1.6 | 150Lb |

Experimental pressure(MPa) | Shell pressure test | 1.5 | 1.5 | 1.5 |

High pressure seal | 1.1 | 1.1 | 1.1 |

Low pressure seal | 0.6 | 0.6 | 0.6 |

Applicable temperature(℃) | PFA: -30~200FEP -30~150GXPO: -10~80 |

Applicable medium | Strong corrosive media such as hydrochloric acid, nitric acid, qing fluoric acid, Cl2, sulfuric acid and aqua regia |

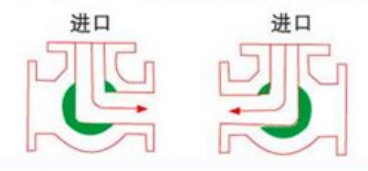

2. Choice of flow directionL型通口三通球阀流向示意图

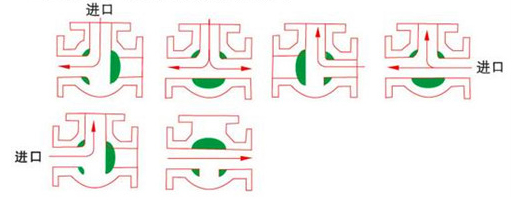

Flow diagram of T-port three-way ball valve

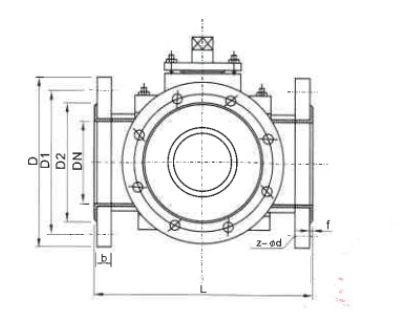

3. Main connection size DN | L | D | D1 | D2 | N-d | f | b |

25 | 165 | 115 | 85 | 65 | 4-14 | 2 | 14 |

32 | 180 | 140 | 100 | 78 | 4-18 | 3 | 16 |

40 | 200 | 150 | 110 | 85 | 4-18 | 3 | 16 |

50 | 200 | 165 | 125 | 100 | 4-18 | 3 | 16 |

65 | 240 | 185 | 145 | 120 | 4-18 | 3 | 18 |

80 | 250 | 200 | 160 | 135 | 8-18 | 3 | 20 |

100 | 280 | 220 | 180 | 155 | 8-18 | 3 | 20 |

125 | 360 | 250 | 210 | 185 | 8-18 | 3 | 22 |

150 | 370 | 285 | 240 | 210 | 8-22 | 3 | 22 |

200 | 550 | 340 | 295 | 265 | 12-22 | 4 | 24 |

250 | 670 | 405 | 355 | 320 | 12-26 | 5 | 26 |

300 | 720 | 460 | 410 | 370 | 12-26 | 5 | 28 |