Design standard | Design and manufacture specification | HG/T3704. GB/T12237 | Performance specification | Pressure level | PN0.6~PN1.6MPa |

Structural length | GB/T12221. HG/T3704 | Strength test | 1.5倍 | ||

Connection size | HG/T20592.GB/T9113 | Seal test | 1.1倍 | ||

Inspection and test | GB/T13927. GB 12220 | Airtight test | 0.6Mpa |

Serial number | Part name | Cast steel |

1 | Left and right valve body | WCB |

2 | Rod sphere | WCB |

3 | packing | WCB |

4 | Packing gland | WCB |

5 | Lining/seat | FEP(F46) PFA PP /PTFE |

6 | bolt | A193-B7 |

7 | nut | A194-2H |

8 | handle | WCC |

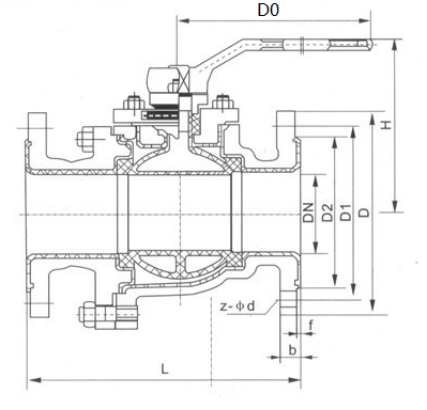

Nominal diameter | Standard value | Reference value | |||||||||

DN | NPS | L | D | D1 | D2 | f | b | N-Фd | Do | H | W(Kg) |

PN0.6(Mpa) | |||||||||||

15 | 1/2 | 140 | 80 | 55 | 40 | 3 | 14 | 4-Ф14 | 120 | 80 | 3 |

20 | 3/4 | 140 | 90 | 65 | 50 | 3 | 16 | 4-Ф14 | 140 | 90 | 4 |

25 | 1 | 150 | 100 | 75 | 60 | 3 | 16 | 4-Ф14 | 160 | 100 | 4.5 |

32 | 11/4 | 165 | 120 | 90 | 70 | 3 | 18 | 4-Ф18 | 160 | 110 | 6.5 |

40 | 11/2 | 180 | 130 | 100 | 80 | 3 | 18 | 4-Ф18 | 200 | 120 | 9.5 |

50 | 2 | 200 | 140 | 110 | 90 | 3 | 20 | 4-Ф18 | 250 | 135 | 10.5 |

65 | 21/2 | 220 | 160 | 130 | 110 | 3 | 20 | 4-Ф18 | 300 | 145 | 15.5 |

80 | 3 | 250 | 190 | 150 | 128 | 3 | 20 | 8-Ф18 | 350 | 180 | 20 |

100 | 4 | 280 | 210 | 170 | 148 | 3 | 22 | 8-Ф18 | 350 | 195 | 28 |

125 | 5 | 325 | 240 | 200 | 178 | 3 | 22 | 8-Ф18 | 350 | 210 | 40 |

150 | 6 | 365 | 265 | 225 | 202 | 3 | 24 | 8-Ф22 | 500* | 450 | 70 |

200 | 8 | 457 | 320 | 280 | 258 | 3 | 24 | 8-Ф22 | 240* | 490 | 110 |

250 | 10 | 533 | 375 | 335 | 312 | 3 | 26 | 12-Ф22 | 240* | 550 | 220 |

300 | 12 | 610 | 440 | 395 | 365 | 3 | 28 | 12-Ф22 | 320* | 600 | 280 |

350 | 14 | 686 | 490 | 445 | 415 | 3 | 30 | 16-Ф22 | 320* | 675 | 410 |

Nominal diameter | Standard value | Reference value | |||||||||

DN | NPS | L | D | D1 | D2 | f | b | N-Фd | Do | H | W(Kg) |

PN1.0(Mpa) | |||||||||||

15 | 1/2 | 140 | 95 | 65 | 45 | 3 | 14 | 4-Ф14 | 120 | 80 | 3 |

20 | 3/4 | 140 | 105 | 75 | 55 | 3 | 16 | 4-Ф14 | 140 | 90 | 4 |

25 | 1 | 150 | 115 | 85 | 65 | 3 | 16 | 4-Ф14 | 160 | 100 | 4.5 |

32 | 11/4 | 165 | 140 | 100 | 75 | 3 | 18 | 4-Ф18 | 160 | 110 | 6.5 |

40 | 11/2 | 180 | 150 | 110 | 85 | 3 | 18 | 4-Ф18 | 200 | 120 | 9.5 |

50 | 2 | 200 | 165 | 125 | 100 | 3 | 20 | 4-Ф18 | 250 | 135 | 10.5 |

65 | 21/2 | 220 | 185 | 145 | 120 | 3 | 20 | 4-Ф18 | 300 | 145 | 15.5 |

80 | 3 | 250 | 200 | 160 | 135 | 3 | 20 | 8-Ф18 | 350 | 180 | 20 |

100 | 4 | 280 | 220 | 180 | 155 | 3 | 22 | 8-Ф18 | 350 | 195 | 28 |

125 | 5 | 320 | 250 | 210 | 185 | 3 | 22 | 8-Ф18 | 350 | 210 | 40 |

150 | 6 | 360 | 285 | 240 | 210 | 3 | 24 | 8-Ф22 | 500* | 450 | 70 |

200 | 8 | 457 | 340 | 295 | 265 | 3 | 24 | 8-Ф22 | 240* | 490 | 110 |

250 | 10 | 533 | 395 | 350 | 320 | 3 | 26 | 12-Ф22 | 240* | 550 | 220 |

300 | 12 | 610 | 445 | 400 | 370 | 3 | 28 | 12-Ф22 | 320* | 600 | 280 |

350 | 14 | 686 | 505 | 460 | 430 | 3 | 30 | 16-Ф22 | 320* | 675 | 410 |

Nominal diameter | Standard value | Reference value | |||||||||

DN | NPS | L | D | D1 | D2 | f | b | N-Фd | Do | H | W(Kg) |

PN1.6(Mpa) | |||||||||||

15 | 1/2 | 140 | 95 | 65 | 45 | 3 | 14 | 4-Ф14 | 120 | 80 | 3 |

20 | 3/4 | 140 | 105 | 75 | 55 | 3 | 16 | 4-Ф14 | 140 | 90 | 4 |

25 | 1 | 150 | 115 | 85 | 65 | 3 | 16 | 4-Ф14 | 160 | 100 | 4.5 |

32 | 11/4 | 165 | 140 | 100 | 75 | 3 | 18 | 4-Ф18 | 160 | 110 | 6.5 |

40 | 11/2 | 180 | 150 | 110 | 85 | 3 | 18 | 4-Ф18 | 200 | 120 | 9.5 |

50 | 2 | 200 | 165 | 125 | 100 | 3 | 20 | 4-Ф18 | 250 | 135 | 10.5 |

65 | 21/2 | 220 | 185 | 145 | 120 | 3 | 20 | 4-Ф18 | 300 | 145 | 15.5 |

80 | 3 | 250 | 200 | 160 | 135 | 3 | 20 | 8-Ф18 | 350 | 180 | 20 |

100 | 4 | 280 | 220 | 180 | 155 | 3 | 22 | 8-Ф18 | 350 | 195 | 28 |

125 | 5 | 320 | 250 | 210 | 185 | 3 | 22 | 8-Ф18 | 350 | 210 | 40 |

150 | 6 | 360 | 285 | 240 | 210 | 3 | 24 | 8-Ф22 | 500* | 450 | 70 |

200 | 8 | 457 | 340 | 295 | 265 | 3 | 26 | 12-Ф22 | 240* | 490 | 110 |

250 | 10 | 533 | 405 | 355 | 320 | 3 | 28 | 12-Ф26 | 240* | 550 | 220 |

300 | 12 | 610 | 460 | 410 | 375 | 3 | 32 | 12-Ф26 | 320* | 600 | 280 |

350 | 14 | 686 | 520 | 470 | 435 | 3 | 35 | 16-Ф26 | 320* | 675 | 410 |