Product introduction

※ Product name:Fluorine lined upper and lower open discharge valve

※ Product model:SF/XF4C1F416-Q

※ Product structure: straight through type

※ Product specification:DN15-200

※ Shell material: carbon steel、304、316L

※ Lining material:FEP(F46)、PFA

First, product overview

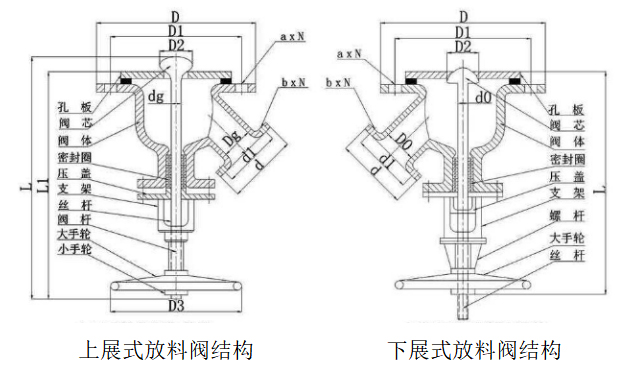

The bottom discharge valve of fluorine-lined tank can be divided into two kinds according to its structural form: fluorine-lined upper spread type discharge valve and fluorine-lined lower spread type discharge valve. Its inner cavity and valve flap are lined with corrosion resistance and aging resistance polyperfluorine-ethylene propylene (F46) or polytetrafluoroethylene (F4) by high pressure injection molding process, which has reliable corrosion resistance and sealing property. The applicable temperature of this product: poly (perfluorinated ethylene propylene) lining is -85℃~+150℃, polytetrafluoroethylene lining can reach -200℃~+180℃. Suitable for all kinds of industrial production of liquid discharge, in a variety of acid, alkali, salt and other strong corrosive media can work well.

Second, the main characteristics

1, fluorine plastic discharge valve is mainly composed of valve body, valve disc, sealing ring, stem, support, valve gland, handwheel, flange, nut, positioning screw and other parts, the valve cavity and the surface of the valve disc are wrapped with a layer of corrosion resistance, aging resistance of polyperfluorinated ethylene propylene or polytetrafluoroethylene, this material has reliable corrosion resistance and sealing.

2, this product is a soft sealing structure, sealing structure is reasonable, can achieve zero leakage standards, suitable for all kinds of industrial production of liquid discharge, especially in dilute acid, concentrated acid and other media can work well.

3, lined fluorine plastic discharge valve using fluorine plastic material is very good corrosion resistance and strong temperature resistance, successfully solved the reaction tank to cope with various nature of the material situation, it depends on flange connection, manual, pneumatic, electric three transmission modes, suitable for oil, acid, corrosive media, etc.

Third, the upper valve and the lower valve difference

1. Applicability of upper and lower opening type discharge valve

The discharge valve is mainly used for discharging materials at the bottom of storage tanks, reaction tanks and other containers. The valve is connected with the equipment by flange or butt welding and is located at the bottom, eliminating the residual phenomenon of process media usually at the outlet of the container. According to the needs of the actual situation, it can be divided into the upper type and the lower type. Upspread type for the reaction kettle with agitator discharge valve; The downspread discharge valve is used for the reaction kettle discharge of frame anchor agitator.

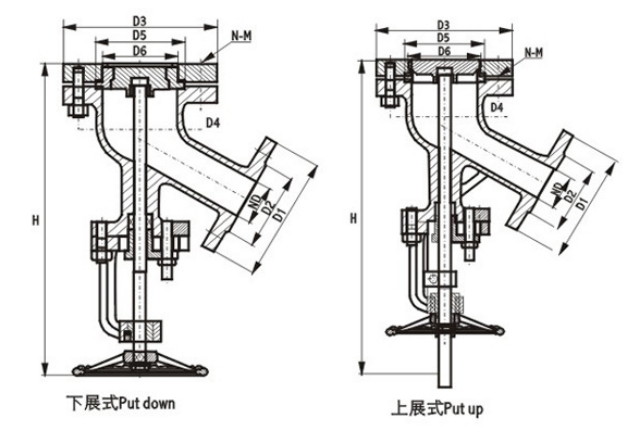

2. Structural differences

3. The difference between the opening and closing torque of the upper and lower developing discharge valves

The upspread discharge valve is open for the disc to move up the valve. When opened, the valve needs to overcome the medium force. When opened, the closing torque is larger.

The downward expansion type discharge valve for the valve disc (plunger) downward movement of the valve to open, open the direction of motion and the medium force is the same, so the opening is smaller than the closing torque.

4. The difference between the opening and closing stroke of the upper and lower developing discharge valves

The opening and closing stroke is different, and the installation size has small opening and closing stroke and small installation height of the upper and lower opening and closing valves. Plunger discharge valve according to the plunger structure and movement mode is divided into lifting rod and rotating rod two structural forms, lifting rod structure type it requires a large installation space, but can be based on the plunger movement mode and position intuitively judge the valve opening and closing and position. The installation height of the rotating rod structure is small, in the process of opening and closing the plunger only rotating motion, it should be based on the opening and closing position indicator to judge the valve opening and closing and position.

Product parameter

First, the main parts of the material table Serial number | Part name | Material name |

1 | Valve body | WCB | CF8 | CF3 | CF8M | CF3M |

2 | Packing gland | WCB | CF8 | CF3 | CF8M | CF3M |

3 | support | WCB | CF8 | CF3 | CF8M | CF3M |

4 | Valve seat | 2Cr13 | 304 | 304L | 316 | 316L |

5 | Lead screw | 2Cr13 | 304 | 304L | 316 | 316L |

6 | disc | 2Cr13 | 304 | 304L | 316 | 316L |

7 | gasket | graphite+304 | 304+PTFE | 304L+PTFE | 316+PTFE | 316L+PTFE |

8 | bolt | 35CrMoA | 1Cr17Ni2 | 1Cr17Ni2 | 1Cr17Ni2 | 1Cr17Ni2 |

9 | nut | 45 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

10 | Lining material | Polyperfluorinated ethylene propylene (F46), polytetrafluoroethylene (F4) |

Second, the main technical specification table Design standard | HG 5-6-81《Hand spread cast steel discharge valve》、HG 5-7-81《Hand spread down cast steel discharge valve》 |

Flange standard | JB/T 79、GB/T 9112、HG/T 20592、HG/T 20615、SH/T 3406、ASME B16.5等 |

Inspection and test standards | JB/T 9092-1999 |

Applicable medium | Crystal particles, powders, acids and bases, etc |

Applicable temperature | ≤150℃ |

Third, the main appearance size table

1. Size information of upspread type

DN | Upper France | Upper France | Lower flange | Sealing seat |

D1 | D2 | D3 | D4 | D5 | D6 |

25 | 115 | 80 | 115 | 85 | | |

32 | 135 | 100 | 135 | 100 | | |

40 | 145 | 110 | 145 | 110 | 80 | 60 |

50 | 165 | 125 | 160 | 125 | 85 | 70 |

65 | 180 | 145 | 180 | 145 | 130 | 85 |

80 | 195 | 160 | 195 | 160 | 135 | 95 |

100 | 215 | 180 | 215 | 180 | 160 | 130 |

125 | 245 | 210 | 245 | 210 | 160 | 140 |

150 | 280 | 240 | 280 | 240 | 185 | 165 |

200 | 335 | 295 | 335 | 295 | / | / |

Downspread size information

DN | Upper France | Upper France | Lower flange | Sealing seat |

D1 | D2 | D3 | D4 | D5 | D6 |

25 | 115 | 85 | 135 | 100 | 70 | 40 |

32 | 135 | 100 | 145 | 110 | 75 | 55 |

40 | 145 | 110 | 160 | 125 | 85 | 65 |

50 | 165 | 125 | 180 | 145 | 100 | 70 |

65 | 180 | 145 | 195 | 160 | 135 | 90 |

80 | 195 | 160 | 215 | 180 | 155 | 130 |

100 | 215 | 180 | 245 | 210 | 180 | 135 |

125 | 245 | 210 | 280 | 245 | 195 | 145 |

150 | 280 | 240 | 335 | 295 | 210 | 185 |

200 | 335 | 295 | 405 | 355 | / | / |