零件名称 | 精铸球墨铸铁 | 碳钢 | 不锈钢 | |||

QT | C | P | R | PL | RL | |

阀体、阀盖、阀瓣 | QT400 | WCB | CF8 | CF 8M | CF3 | CF3M |

内衬材料 | FEP(F46)、PTFE(F4)、PFA(可溶性聚四氟乙烯)、PO(聚烯烃)、PE(超高分子量聚乙烯) | |||||

螺栓 | 35 | 35 | 1Cr17Ni2 | 1Cr17Ni2 | 1Cr18Ni9 | 1Cr18Ni9 |

螺母 | 45 | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 |

技术标准 | |

设计和制造 | GB/T12235 GB/T12236 |

结构长度 | HG/T3704-2003 GB12221ASME B16.10 |

法兰尺寸 | GB/T9113.1、ANSI B16.5a |

结构形式 | 升降立式、旋转式、升降直通式 |

公称压力 | 0.6、1.0、1.6、2.5MpaClass150 JIS 10K |

压力试验 | GB/T13927-92API598 |

基本型号 | ||

H41F4 | H42F4 | H441F4 |

H41F46 | H42F46 | H44F46 |

H41PFA | H42PFA | H44PFA |

公称直径 | DN15-DN400 | |||

压力 | 1.0Mpa 1.6Mpa 150LB | |||

序号 | 名称 | 材料明细 | ||

1 | 阀体,阀瓣,阀盖 | A216WCB+衬里材质 | A351 CFB/A351 | A351 CF3/A351CF3M+衬里材质 |

2 | 球 | PTFE | ||

3 | 衬里材质 | FEP PFA GXPO | ||

4 | 螺栓 | A193 B7 | A320 B8 | A193 B8M |

设计标准 | HG/T 3704 GB/T 12235 | AP16D | ||

结构长度 | HG/T 3704 GB/T 12221 | ASME B16.10 | ||

法兰形式尺寸 | HG/T 20592 GB/T 9119 | ASME B16.5 JIS B2220 | ||

检验与试验 | GB/T 13927 JB/T 9092 | API 598 | ||

公称压力(MPa) | 1.0 | 1.6 | 150LB | |

实验压力 | 壳体试压 | 1.5 | 1.5 | 1.5 |

| 高压密封 | 1.1 | 1.1 | 1.1 |

| 低压密封 | 0.6 | 0.6 | 0.6 |

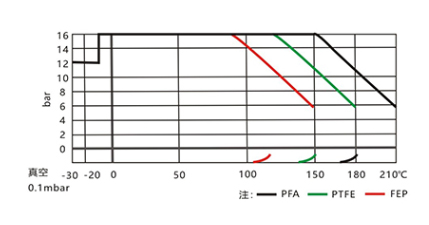

适用温度 ℃ | PFA -30~200 FEP -30~150 GXPO -10~80 | |||

适用介质 | 盐酸、硝酸、氢氟酸、液氯、硫酸、王水等强腐蚀性介质 | |||

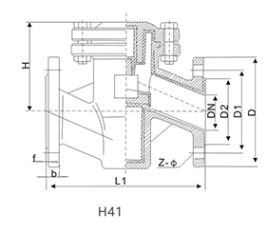

DN | L1 | L2 | D | D1 | D2 | N-Фd | f | b | H | Wt(Kt) |

| 15 | 130 | 110 | 95 | 65 | 45 | 4-14 | 2 | 14 | 82 | 6.5 |

20 | 150 | 117 | 105 | 76 | 55 | 4-14 | 2 | 14 | 82 | 5 |

25 | 160 | 127/100 | 115 | 86 | 65 | 4-14 | 2 | 14 | 98 | 6 |

32 | 180 | 140/110 | 140 | 100 | 78 | 4-18 | 3 | 16 | 110 | 7.5 |

40 | 200 | 165/125 | 150 | 110 | 85 | 4-18 | 3 | 16 | 118 | 9.5 |

50 | 230 | 178/140 | 165 | 125 | 100 | 4-18 | 3 | 16 | 138 | 13 |

65 | 290 | 190/160 | 185 | 145 | 120 | 4-18 | 3 | 18 | 156 | 19.5 |

80 | 310 | 203/185 | 200 | 160 | 135 | 8-18 | 3 | 20 | 160 | 27 |

100 | 350 | 229/210 | 220 | 180 | 155 | 8-18 | 3 | 20 | 185 | 35 |

125 | 400 | 280/250 | 250 | 210 | 185 | 8-18 | 3 | 22 | 208 | 56 |

| 150 | 480 | 300 | 285 | 240 | 210 | 8-23 | 3 | 24 | 245 | 75 |

| 200 | 600 | 380 | 340 | 295 | 265 | 8-23 | 3 | 26 | 298 | 118 |

| 250 | 670 | 420 | 395 | 350 | 320 | 12-23 | 4 | 28 | 342 | 165 |

| 300 | 850 | 425 | 445 | 400 | 368 | 12-23 | 4 | 28 | 210 |

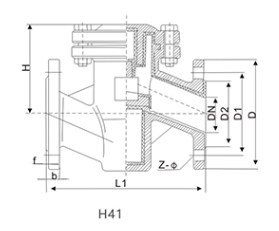

DN | L1 | L2 | D | D1 | D2 | N-Фd | f | b | H | Wt(Kt) |

| 15 | 130 | 110 | 95 | 65 | 45 | 4-14 | 2 | 14 | 82 | 4 |

20 | 150 | 117 | 105 | 75 | 55 | 4-14 | 2 | 14 | 82 | 5 |

25 | 160 | 127/100 | 115 | 85 | 65 | 4-14 | 2 | 14 | 98 | 6 |

32 | 180 | 140/110 | 140 | 100 | 78 | 4-18 | 3 | 16 | 110 | 7.5 |

40 | 200 | 165/125 | 150 | 110 | 85 | 4-18 | 3 | 16 | 118 | 9.5 |

50 | 230 | 178/140 | 165 | 125 | 100 | 4-18 | 3 | 16 | 138 | 13 |

65 | 290 | 190/160 | 185 | 145 | 120 | 4-18 | 3 | 18 | 156 | 19.5 |

80 | 310 | 203/185 | 200 | 160 | 135 | 8-18 | 3 | 20 | 160 | 27 |

100 | 350 | 229/210 | 220 | 180 | 155 | 8-18 | 3 | 20 | 185 | 35 |

125 | 400 | 280/250 | 250 | 210 | 185 | 8-18 | 3 | 22 | 208 | 56 |

| 150 | 480 | 300 | 285 | 240 | 210 | 8-23 | 3 | 24 | 245 | 75 |

| 200 | 600 | 380 | 340 | 295 | 265 | 12-23 | 3 | 26 | 298 | 118 |

| 250 | 670 | 420 | 405 | 355 | 320 | 12-25 | 4 | 28 | 342 | 165 |

| 300 | 850 | 425 | 460 | 410 | 375 | 12-25 | 4 | 29 |

DN | L1 | L2 | D | D1 | D2 | N-Фd | f | b | H | Wt(Kt) |

| 15 | 130 | 110 | 95 | 65 | 45 | 4-14 | 2 | 16 | 82 | 6.5 |

20 | 150 | 117 | 105 | 75 | 55 | 4-14 | 2 | 16 | 82 | 7 |

25 | 160 | 127/100 | 115 | 85 | 65 | 4-14 | 2 | 16 | 98 | 8 |

32 | 180 | 140/110 | 140 | 100 | 78 | 4-18 | 3 | 18 | 110 | 11 |

40 | 200 | 165/125 | 150 | 110 | 85 | 4-18 | 3 | 18 | 118 | 15 |

50 | 230 | 178/140 | 165 | 125 | 100 | 4-18 | 3 | 20 | 138 | 17.5 |

65 | 290 | 190/160 | 185 | 145 | 120 | 8-18 | 3 | 22 | 156 | 26 |

80 | 310 | 203/185 | 200 | 160 | 135 | 8-18 | 3 | 22 | 160 | 36 |

100 | 350 | 229/210 | 235 | 190 | 160 | 8-23 | 3 | 24 | 185 | 44 |

125 | 400 | 280/250 | 270 | 220 | 188 | 8-25 | 3 | 28 | 208 | 60 |

| 150 | 480 | 300 | 300 | 250 | 218 | 8-25 | 3 | 30 | 245 | 81 |

| 200 | 600 | 380 | 360 | 310 | 278 | 12-25 | 3 | 34 | 298 | 137 |

| 250 | 670 | 420 | 425 | 370 | 332 | 12-30 | 4 | 36 | 342 | 173 |

| 300 | 850 | 425 | 485 | 410 | 375 | 16-30 | 4 | 39 |

DN | L1 | L2 | D | D1 | D2 | N-Фd | f | b | H | Wt(Kt) |

| 1/2 | 130 | 110 | 89 | 60.5 | 35 | 4-16 | 2 | 12 | 82 | 4 |

3/4 | 150 | 117 | 98 | 70.0 | 43 | 4-16 | 2 | 12 | 82 | 5 |

1 | 160 | 127/100 | 108 | 79.5 | 51 | 4-16 | 2 | 12 | 98 | 6 |

11/4 | 180 | 140/110 | 117 | 89.0 | 64 | 4-16 | 2 | 13 | 110 | 7.5 |

11/2 | 200 | 165/125 | 127 | 98.5 | 73 | 4-16 | 2 | 15 | 118 | 9.5 |

2 | 230 | 178/140 | 152 | 120.5 | 92 | 4-19 | 2 | 16 | 138 | 13 |

21/2 | 290 | 190/160 | 179 | 139.5 | 105 | 4-19 | 2 | 18 | 156 | 19.5 |

3 | 310 | 203/185 | 190 | 152.5 | 127 | 4-19 | 2 | 19 | 160 | 27 |

4 | 350 | 229/210 | 229 | 190.5 | 157 | 8-19 | 2 | 24 | 185 | 35 |

5 | 400 | 280/250 | 254 | 216.0 | 186 | 8-22 | 3 | 24 | 208 | 56 |

| 6 | 480 | 300 | 279 | 241.5 | 216 | 8-22 | 3 | 26 | 245 | 75 |

| 8 | 600 | 380 | 343 | 298.5 | 270 | 8-22 | 3 | 29 | 298 | 118 |

| 10 | 670 | 420 | 406 | 362.0 | 324 | 12-25 | 3 | 31 | 342 | 165 |

| 12 | 850 | 425 | 485 | 432 | 381 | 12-25 | 4 | 34.5 | 205 |