First, product overview

Electric fluorine lined butterfly valve, composed of Angle travel full electronic electric actuator and fluorine lined butterfly valve body assembly of two parts. Valve body cavity and valve plate are lined with high pressure injection molding process corrosion resistance, aging resistance of polytetrafluoroethylene, so it has reliable corrosion resistance and sealing. This series of pneumatic fluorine lined butterfly valve is mainly suitable for chemical, pharmaceutical, food, paper, water treatment and other industries to acid, alkali and other strong corrosive medium regulation or cut off. Valve body, valve seat and spool lining integration, valve work, only the valve body lining and lining plastic plate contact with the medium, completely achieve zero leakage of the medium, with tight sealing performance, long service life.

Second, product features

1. The valve has the sealing function that the closer the valve is closed, and the sealing performance is reliable.

2, tetrafluoroseal can be located on the valve body, can also be located on the butterfly plate, can be applicable to different characteristics of the medium for the user to choose.

4, the butterfly plate adopts frame structure, high strength, large flow area, small flow resistance.

5, the overall paint, can effectively prevent corrosion and as long as the replacement of the sealing seat sealing material, can be used in different media.

6, the valve has bidirectional sealing function, installation is not controlled by the flow of the medium, also is not affected by the spatial position, can be installed in any direction. Flexible operation, labor saving, convenient.

Third, product application

Fluorine lined butterfly valve is suitable for producing furnace, gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting and power generation environmental protection engineering system in the transmission of various corrosive, non-corrosive fluid medium pipeline, used to regulate and cut off the flow of media.

Fourth, main performance parameters

Nominal diameter: DN50 ~ 350

Working power supply: AC220V/DC24V

Applicable temperature: natural rubber ≤85℃ EPDM ≤100℃ PTFE ≤120℃

Connection mode: flange type and clamp type

Control signal: 4 to 20mA and 1 to 5VDC

Feedback signal: 4 ~ 20mA and 1 ~ 5VDC

Basic error: ≤0.5%

Dead zone: ≤0.4%

Protection level: IP68

Design standard: GB12238

Structure length: GB12221

Flange standard: GB/T20592 GB/T9112, etc

Adjustment mode: cut off/adjust

Scope of application: building materials processing, industrial boiler, furnace cellar flue gas, sulfur dioxide, etc

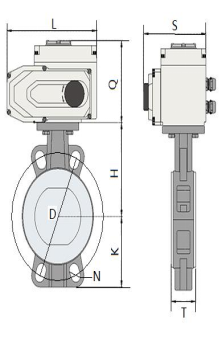

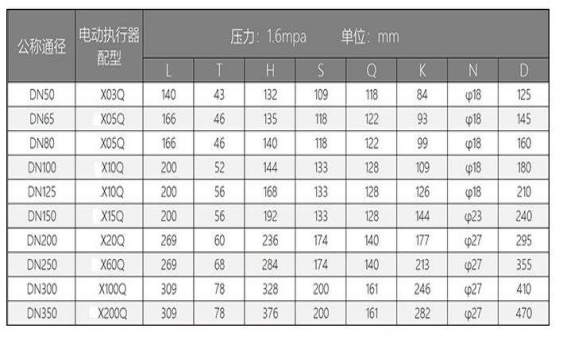

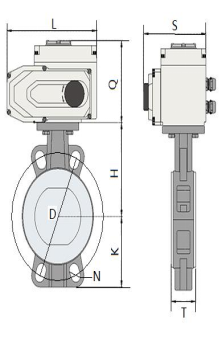

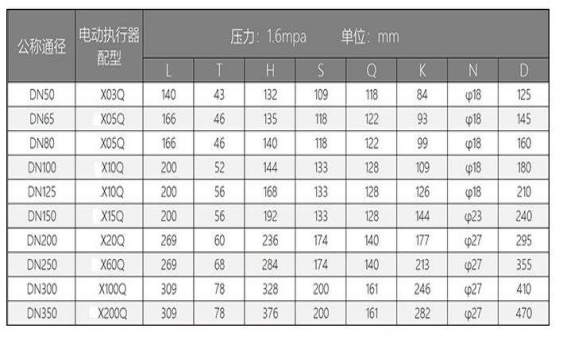

Fifth, electric disc valve size

Note: The above size is for reference only, the specific size is based on physical objects.

Notice to quotation:

1, valve body parameters: caliber, working pressure, valve body material, using medium, connection form and other parameters

2, actuator: actuator form, control mode, control signal (4-20MA)

Please try to provide detailed parameters about each standard pneumatic ball valve, to facilitate our technical personnel for your accurate selection.