※ Product name:Fluorine lined discharge ball valve

※ Product model:Q41F46-16C

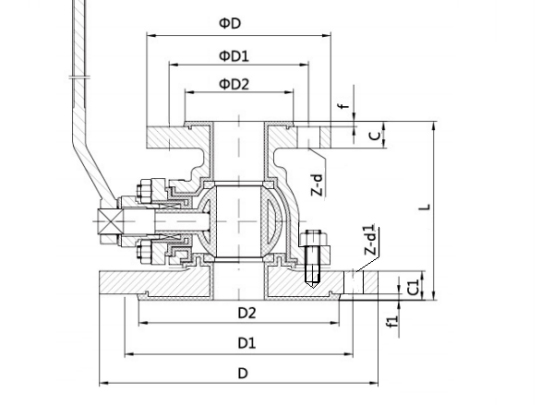

※ Product specification:DN15-1000

※ Shell material:Carbon steel、304、316L

※ Lining material:FEP(F46)、PFA

First、Overview

Fluorine lined ball valve is an extension of the fluorine lined ball valve, designed for the opening and closing control of a variety of strong corrosive media, the two ends of the valve flange size, one end for the standard flange and the other end for the reaction kettle bottom discharge hole supporting flange, very convenient can be connected to the bottom of the reaction kettle. Its structure is the floating straight through type, the connection form is the flange, the valve shell is made of carbon steel lined with fluorine plastic, the valve ball and the valve stem integrated metal insert outsourcing fluorine plastic process, has the characteristics of good corrosion resistance sealing, flexible opening and closing, fast and beautiful appearance, high strength, durable. It is a wide range of corrosion resistant valves used in modern industrial processes. Fluorine lined feeding ball valve adopts fluorine plastic lining technology, valve body adopts investment precision casting, high strength, smooth appearance, and liquid flow parts are all fluorine plastic, so it can be used in the range of -50C~180C for a long time in any concentration of corrosive pipeline, pipeline work. The working principle of the fluorine lined ball valve is to rotate the disc to make the valve unblocked or blocked. The disc and the body inside are all made of fluorine plastic lined plastic process. It has the advantages of light switch, small size, reliable sealing, simple structure, convenient maintenance, wide range of use and so on.

Second、Fluorine lined feed ball valve features

1.Ball valve with fluorine plastic lining layer, with high chemical stability, can be applied to any strong corrosive chemical media;

2.Full diameter, floating ball structure, the valve in the whole range of pressure to be closed without leakage, more convenient for the pipeline system through the ball line cleaning and pipeline maintenance;

3.The ball of opening and closing parts and valve stem casting (forging) as a whole, eliminate the possibility of valve stem impact bearing parts due to pressure changes, fundamentally ensure the safety in use;

4.

set | Design and manufacture specification | HG/T3704.GB/T12237 | sex | Pressure level | PN0.6~PN1.6MPa |

Structural length | GB/T12221. HG/T3704 | Strength test | 1.5times | ||

Connection size | HG/T20592.GB/T9113 | Seal test | 1.1times | ||

Inspection and test | GB/T13927. GB 12220 | Airtight test | 0.6Mpa |

Serial number | Part name | Cast steel |

1 | Left and right valve body | WCB |

2 | Rod sphere | WCB |

3 | packing | WCB |

4 | Packing gland | WCB |

5 | Lining/seat | FEP(F46) PFA PP /PTFE |

6 | bolt | A193-B7 |

7 | nut | A194-2H |

8 | handle | WCC |

PN1.0 (0.6)MPa | ||||||

DN(mm) | ФD-D | L | ФD1-D1 | N-d/d1 | f/f1 | W(Kg) |

25/50 | 115/160 | 150 | 85/110 | 4-14/4-18 | 3/3 | 6 |

32/65 | 135/180 | 165 | 100/130 | 4-18/4-18 | 3/3 | 7 |

40/65 | 145/180 | 180 | 110/130 | 4-18/4-18 | 3/3 | 8 |

40/100 | 145/215 | 150 | 110/170 | 4-18/4-18 | 3/3 | 9 |

50/80 | 160/195 | 200 | 125/150 | 4-18/4-18 | 3/3 | 10 |

50/125 | 160/245 | 170 | 125/200 | 4-18/8-18 | 3/3 | 11.5 |

65/100 | 180/215 | 220 | 145/170 | 4-18/4-18 | 3/3 | 15 |

65/125 | 180/245 | 220 | 145/200 | 4-18/8-18 | 3/3 | 17 |

80/125 | 195/245 | 250 | 160/200 | 8-18/8-18 | 3/3 | 22 |

80/150 | 195/280 | 250 | 160/225 | 8-18/8-18 | 3/3 | 24 |

100/150 | 215/280 | 280 | 180/225 | 8-18/8-18 | 3/3 | 32 |

100/200 | 215/320 | 280 | 180/280 | 8-18/8-18 | 3/3 | 36 |