Product introduction

※ Product name:Pressure relief manhole

※ Product model:XAXY-型号(DN)

※ Product specification:DN500-DN750

※ Shell material: carbon steel、304、316L

※ Lining material:FEP(F46)、PFA

First, product overview

The emergency pressure relief manhole is an emergency ventilation device installed on the top of the storage tank, which is usually used in combination with the breathing valve. It is a device to protect the storage tank since it can avoid accidents caused by the sudden overpressure in the tank caused by accidental rabbit. It is especially suitable for the arch atmospheric pressure tank with boron for storage materials and nitrogen capped. Bribe pressure discharge, Xing flexible compact structure, good sealing performance, can be

And so on. The product adopts all-weather sealing structure, with a spring counterweight to adjust the opening and closing of the pressure relief cover.

Second, the working principle

The whole emergency rib pressure relief manhole is made of anti-corrosion material. The adjustable spring of the bottle clings into the top cap to keep the valve sealed and the direct force reaches the value. The fluorine rubber material sole is of great characteristic to ensure sealing. Under the condition that the fire retardant breathing valve works normally, the emergency pressure relief manhole is basically kept sealed and the storage tank is under normal pressure. When the normal operation of the breathing valve can not meet the sudden overpressure of the tank due to accidental reasons, the pressure relief manhole of the pressure relief cover automatically open for emergency pressure relief, so that the tank pressure to maintain normal; When the tank excitation rapid decompression or super vacuum, the suction valve will open the rapid suction atmosphere, maintain the normal pressure in the tank; When there are sparks and flames in the suction atmosphere, the fire retardant layer acts as a "wall effect" to prevent the flame from passing through, so as to protect the tank.

Product parameter

First, the main technical parameters

Second, shell material: carbon steel, aluminum alloy, stainless steel (SUS304, SUS304L, SUS316, SUS316L), lined fluorine, plastic

Third, internal core: disc, valve seat, stem, valve sleeve. Internal core material: stainless steel or PTFE.

Fourth, sealing ring material: PTFE.

Fifth, the ambient temperature: -40~+60OC.

Sixth, operating pressure:

Seventh, Type A: +355Pa (+36mmH20), -295Pa (-30mmH20)

Eighth, Type B: +980Pa (+100mmH20), -295Pa (-30mmH20)

Ninth, Type C: +1750Pa (+180mmH20), -295Pa (-30mmH20)

Tenth, D type: special pressure, user specified.

Eleventh, fire resistance layer material: stainless steel.

Twelfth, explosion-proof level: BS 5501: IIA, IIB, IIC.

Thirteenth. Flange standard: GB, HG, SH, HGJ, JB, ANSL, JIS and other standards. (User specified, please specify pressure level)

Fourteenth, manufacturing, testing standards: according to (oil tank breathing valve) SY7511-87, (oil tank flame arrester flame resistance performance and test method) GB5908-86 and other standards for manufacturing and acceptance; Or user specified criteria.

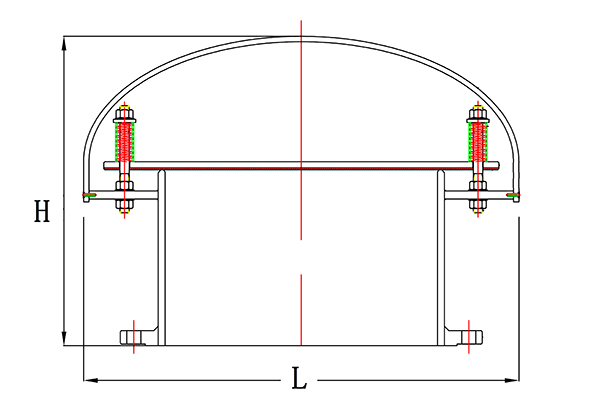

Fifteenth. Main dimensions

Nominal diameter DN | Overall dimension |

H | L |

500 | 380 | 708 |

600 | 480 | 808 |

750 | 600 | 955 |