Product introduction

※Product name:Fluorine-lined breathing manhole

※ Product model:HXF-RK

※ Product specification:DN450-DN750

※ Shell material: carbon steel、304、316L

※ Lining material:FEP(F46)、PFA

First, product overview

According to the provisions of the national standard "Fire Protection Code for Design of Petrochemical Enterprises" (GB50160-90), "the fixed top tank of class A and Class B liquids shall be equipped with flame arrester and breathing valve". Visible breathing valve, flame arrester is the storage tank indispensable safety facilities. It can not only maintain the tank pressure balance, ensure that the tank in the overpressure or vacuum rabbit damage, and can reduce the tank medium volatilization and loss. The valve is installed on the top of the nitrogen sealed tank. It is a safe and energy-saving product to maintain the air pressure balance of the storage tank and reduce the volatilization of the medium. It is often used with the flame arrester.

Fire retardant breathing manhole is a safety emergency ventilation device installed on the top of the tank, usually used in combination with fire retardant breathing valve. Since it can avoid accidents caused by sudden overpressure or vacuum in the tank and damage the tank, it can also play the role of safety and fire protection, and is a safety device to protect the tank, especially suitable for storage materials with nitrogen capped vault atmospheric pressure tank. It has the advantages of constant pressure discharge, constant pressure suction, flexible opening and closing, safe fire resistance, compact structure, good sealing performance, safe and reliable.

Second, the working principle

When the flame arrester breathing valve is working normally, the fire arrester breathing manhole is basically kept sealed and the storage tank is under normal pressure. When the normal operation of the breathing valve cannot meet the sudden overpressure of the tank due to accidental reasons, the pressure relief cover of the breathing manhole automatically opens for emergency pressure relief, so that the pressure in the tank is kept normal; When the pressure in the tank is sharply reduced or super vacuum, the suction valve will be opened to inhale the atmosphere sharply to maintain the normal pressure in the tank; When there are sparks and flames in the suction atmosphere, the fire retardant layer plays the role of "wall effect" to prevent the flame from passing through, so as to protect the safety of the storage tank.

Product parameter

First, the main technical parameters

1, operating pressure: positive pressure +1765Pa (180mmH20) negative pressure -392Pa (-40mmH20)

2. Fire resistance grade: BS5501:II * Standardized

3, the use of temperature: + 50-30 ℃

4, the scope of use: especially suitable for storage materials with nitrogen capped vault atmospheric pressure tank.

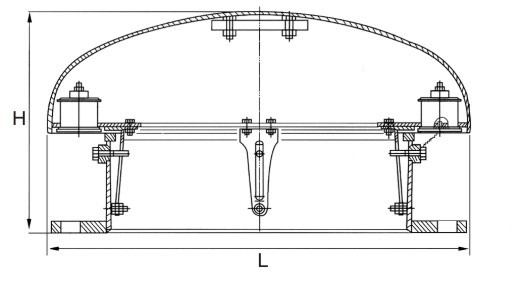

specification | Mounting dimension(mm) |

H | L |

DN450 | 370 | Φ658 |

DN500 | 380 | Φ608 |

DN600 | 480 | Φ808 |

DN700 | 540 | Φ908 |

DN750 | 600 | Φ955 |