1、The installation of compensator shall be carried out in accordance with the requirements of pipe system construction drawings and compensator installation instructions。

2、llation of the compensator pipeline must be properly guided and fixed in order to make the compensator play a role, so the setting of the guide and fixed support must be strictly in accordance with the relevant technical data of the design department

3、Compensator for the bellows is made of thin wall stainless steel plate molding, so during transportation, lifting and welding should pay attention not to knock, scratch, arc, welding splash and other reasons to damage the bellows.

4、Remove foreign bodies in the bellows and pipes before installation to ensure the normal movement of the bellows.Design standard | Design and manufacture specification | GB/T15700. GB/T12777 | Performance specification | Pressure level | PN0.6~PN1.6MPa |

Structural length | GB/T12777 | Strength test | 1.5times | ||

Connection size | HG/T20592.GB/T9113 | Seal test | 1.1times | ||

Inspection and test | GB/T12777 | Airtight test | 0.6Mpa |

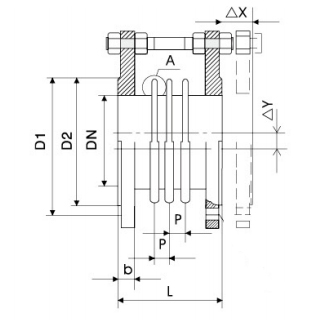

Nominal diameter | Standard length | Wave pitch | Wall thickness | Safe displacement | Flange size | |||||||

DN (mm) | NPS (inch) | 3波L | P | steel b1 | steel b2 | ±△X | ±△Y | D | D1 | D2 | b | Z-Фd |

|

| PN0.6/1.0 (MPa) | ||||||||||

40 | 11/2 | 84 | 10 | 0.5 | 1 | 40 | 10 | 130 | 100 | 80 | 16 | 4-Ф14 |

50 | 2 | 86 | 10 | 0.5 | 1 | 40 | 10 | 140 | 110 | 90 | 16 | 4-Ф14 |

65 | 21/2 | 114 | 12 | 0.7 | 1 | 40 | 10 | 160 | 130 | 110 | 16 | 4-Ф14 |

80 | 3 | 124 | 15 | 0.7 | 1 | 40 | 10 | 185 | 150 | 125 | 18 | 4-Ф18 |

100 | 4 | 129 | 19 | 0.7 | 1.5 | 40 | 10 | 205 | 170 | 145 | 18 | 4-Ф18 |

125 | 5 | 133 | 20 | 0.8 | 1.5 | 40 | 10 | 235 | 200 | 175 | 20 | 8-Ф18 |

150 | 6 | 155 | 23 | 0.8 | 1.5 | 40 | 10 | 260 | 225 | 200 | 20 | 8-Ф18 |

200 | 8 | 168 | 24 | 0.8 | 1.5 | 40 | 10 | 315 | 280 | 255 | 22 | 8-Ф18 |

250 | 10 | 170 | 28 | 1.0 | 1.5 | 40 | 10 | 370 | 335 | 310 | 24 | 12-Ф18 |

300 | 12 | 180 | 30 | 1.0 | 1.5 | 40 | 10 | 435 | 395 | 362 | 24 | 12-Ф22 |

350 | 14 | 186 | 32 | 1.0 | 2 | 40 | 10 | 485 | 445 | 412 | 26 | 12-Ф22 |

400 | 16 | 188 | 35 | 1.2 | 2 | 40 | 10 | 535 | 495 | 462 | 28 | 16-Ф22 |

450 | 18 | 219 | 40 | 1.2 | 2 | 40 | 10 | 590 | 550 | 518 | 28 | 16-Ф22 |

500 | 20 | 238 | 41 | 1.2 | 2 | 40 | 10 | 640 | 600 | 568 | 30 | 20-Ф22 |

600 | 24 | 172 | 45 | 1.2 | 2 | 40 | 10 | 755 | 705 | 670 | 30 | 20-Ф26 |

700 | 28 | 316 | 62 | 1.2 | 2 | 40 | 10 | 860 | 810 | 775 | 32 | 24-Ф26 |

800 | 32 | 322 | 63 | 1.2 | 2 | 40 | 10 | 975 | 920 | 880 | 34 | 24-Ф30 |