衬里、阀座 | 适用温度(℃) | 适用介质 |

PTFE(F4) | ≤180 | 除熔融碱金属、元素氟外的各种浓度的酸、碱、盐、王水、有机酸等强腐蚀性介质 |

PCTFE(F3) | ≤120 | |

FEP(F46) | ≤150 | |

PFA(可熔性F4) | ≤180 | |

PVDF(F2) | ≤100 | |

RPTFE(RF4) | ≤180 |

序号 | 零件名称 | 灰铸铁 | 铸钢 | 不锈耐酸铸钢 | 超低碳不锈耐酸铸钢 | ||

Z | C | P | R | PL | RL | ||

1 | 阀体/阀盖 | HT250 | WCB | CF8 | CF8M | CF3 | CF3M |

2 | 球体/阀杆 | 25 | 2Cr13 | 1Cr18Ni9 | 1Cr18Ni12Mo2Ti | 00Cr18Ni10 | 00Cr17Ni14Mo2 |

3 | 衬里/阀座 | PCTEF(F3),FEP(F46),PFA(可溶F4),PP,PO | |||||

4 | 填料压盖 | WCB | CF8 | CF8M | CF3 | CF3M | |

5 | 填料 | PTFE(F4) | PTFE(F4) | PTFE(F4) | |||

6 | 活节螺栓 | 35 | 1Cr17Ni2 | 1Cr17Ni2 | |||

7 | 阀杆螺母 | ZCuAl10Fe3 | ZCuAl10Fe3 | ZCuAl10Fe3 | |||

8 | 紧固螺栓 | 35 | 1Cr17Ni2 | 1Cr18Ni9Ti | |||

9 | 螺母 | 45 | 0Cr18Ni9 | 0Cr18Ni9 | |||

10 | 手柄 | WCB | WCB | WCB | |||

| 设计标准 | HG/T 3704,GB/T 12235 | BS S160 | ||

| 结构长度 | HG/T 3704,GB/T 12221 | BS S160 | ||

| 法兰形式尺寸 | HG/T 20592,GB/T 9119 | ASME B16.5,JIS B2220 | ||

| 检验与试验 | GB/T 13927,JB/T 9092 | API 598 | ||

| 公称压力(MPa) | 1.0 | 1.6 | 150Lb | |

| 实验压力 (MPa) | 壳体试压 | 1.5 | 1.5 | 1.5 |

| 高压密封 | 1.1 | 1.1 | 1.1 | |

| 低压密封 | 0.6 | 0.6 | 0.6 | |

| 适用温度(℃) | PFA:-30~200 FEP:-30~150 GXPO:-10~80 | |||

| 适用介质 | 盐酸、硝酸、氢氟酸、液氯、硫酸、王水等强腐蚀性介质 | |||

| 零件名称 | 铸钢 | 耐酸不锈钢 | |||

| C | P | R | PL | RL | |

| 阀体/阀盖 | WCB | CF8 | CF8M | CF3 | CF3M |

| 定位夹/填料压盖 | WCB | CF8 | CF8M | CF3 | CF3M |

| 阀杆 | 2Cr13 Ss304 SS410 | ||||

| 衬里材料/阀座 | FEP、PFA、GXPO | ||||

| 阀杆螺母 | 黄铜 | ||||

| 紧固螺栓 | A193 B7 | A320 B8 | A193 B8M | ||

| 螺母 | A194 2H | A194 8 | A194 8M | ||

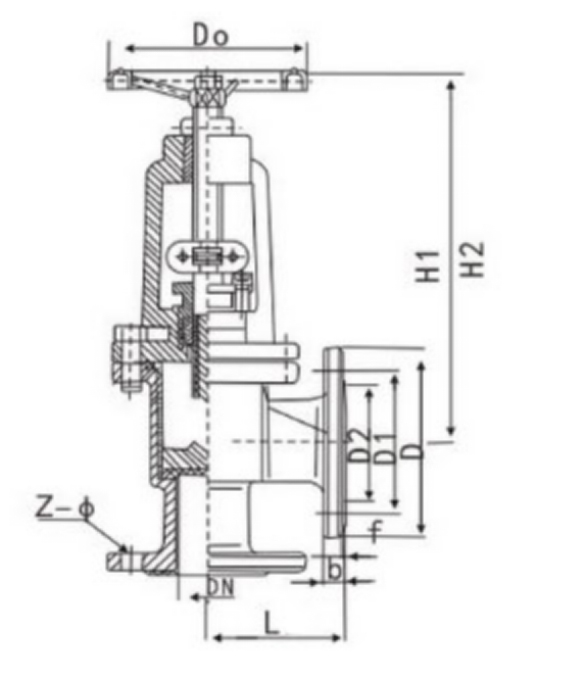

| DN | L | D | D1 | D2 | f | b | N-d | D0 | H1 | H2 | W(Kg) |

| 15 | 90 | 95 | 65 | 43 | 3 | 14 | 4-14 | 100 | 170 | 185 | 7 |

| 20 | 95 | 105 | 75 | 50 | 3 | 14 | 4-14 | 100 | 200 | 220 | 8 |

| 25 | 100 | 115 | 85 | 60 | 3 | 16 | 4-14 | 120 | 205 | 230 | 9 |

| 32 | 105 | 135 | 100 | 68 | 3 | 18 | 4-18 | 140 | 230 | 260 | 10 |

| 40 | 115 | 145 | 110 | 80 | 3 | 18 | 4-18 | 160 | 255 | 292 | 14 |

| 50 | 125 | 160 | 125 | 100 | 3 | 20 | 4-18 | 180 | 270 | 315 | 17 |

| 65 | 145 | 180 | 145 | 115 | 3.5 | 20 | 4-18 | 200 | 335 | 390 | 25 |

| 80 | 155 | 195 | 160 | 130 | 3.5 | 22 | 8-18 | 240 | 395 | 465 | 33 |

| 100 | 175 | 215 | 180 | 150 | 4 | 24 | 8-18 | 280 | 420 | 506 | 45 |

| 125 | 200 | 245 | 210 | 180 | 4 | 26 | 8-18 | 320 | 490 | 600 | 62 |

| 150 | 225 | 280 | 240 | 210 | 4 | 28 | 8-23 | 360 | 520 | 670 | 91 |

| 200 | 275 | 335 | 295 | 260 | 5 | 32 | 12-18 | 400 | 590 | 740 | 140 |

| 250 | 325 | 405 | 355 | 319 | 5 | 36 | 12-26 | 450 | 660 | 840 | 220 |

| 300 | 375 | 460 | 410 | 370 | 6 | 40 | 12-26 | 500 | 710 | 900 | 305 |