First, pneumatic line fluorine ball valve product overview

Q641F46 pneumatic lined fluorine ball valve is designed for the automatic opening and closing control of various corrosive medium pipelines, widely used in petroleum, chemical, dyeing, acid and alkali manufacturing industries, is currently one of the most ideal choice of anticorrosive valve equipment. Pneumatic lined four-fluorine ball valve is fluorine plastic lining, the shell is investment precision casting, high strength, smooth appearance, and the liquid contact part of all fluorine plastic, so pneumatic lined fluorine ball valve can be used in the range of -20℃ ~ 180℃ for a long time in any concentration of corrosive pipeline, pipeline work.

Second, pneumatic lined fluorine ball valve structure principle and advantages

The working principle of pneumatic lined fluorine ball valve is to rotate the valve love to make the valve unblocked or blocked, the valve love and valve body inside all made of fluorine plastic, the shell is made of investment precision casting, high strength, smooth appearance, and liquid contact part of all fluorine plastic, is specially designed to control the opening and closing of various corrosive media and the ball valve, it has a light switch, small size, Reliable sealing, simple structure, convenient maintenance, wide range of use and so on.

Pneumatic ball valve lined with fluorine advantages:

1. Fluorine plastic seal, with high chemical stability, can be applied to any strong corrosive chemical media;

2. Adopt full diameter, floating ball structure, the valve can be closed in the whole pressure range without leakage, more convenient for the pipeline system through the ball line sweeping and pipeline maintenance;

3. The ball of opening and closing parts is integrated with the valve stem casting (forging), which eliminates the possibility of the valve stem impacting the bearing parts due to pressure changes, and fundamentally ensures the safety of use in the project;

4. The structure is compact and reasonable, the body cavity space is minimum, reducing the medium retention, in addition, the special molding process, the sealing surface density is good, and the herringbone PTFE packing combination, so that the valve to zero leakage.

| Nominal diameter DN(mm) | 15~300 | Actuator type number | GT、AT、AW series single and double acting pneumatic actuator |

| Nominal pressure(MPa) | 1.0、1.6 MPa | Air supply pressure | 0.4~0.7MPa |

| Valve body form | Two-stage valve body (fixed sphere) | Air source interface | G1/4"、G1/8"、G3/8"、G1/2" |

| Connection form | Flange type | Ambient temperature | -30~+70℃ |

| Spool form | "O" ball spool | Mode of action | Single acting actuator, double acting actuator |

| Sealing packing | Teflon(PTFE) | Accessories available | Positioner, solenoid valve, air filter pressure reducer, position keeping valve, travel switch, valve position transmitter, hand wheel mechanism, etc |

| Flow characteristic | Approximate fast opening type | Adopt new pneumatic actuator, double acting and single acting (spring return), rack and pinion drive, safe and reliable. |

| 动作范围 | 0~90° | 1、Gear type double piston, large output torque, small volume. |

| Leakage Q | Soft seal: Zero leakage | 2、Cylinder selection of aluminum gold material, light weight, beautiful appearance. |

| Applicable temperature | PTFE≤180℃ | 3、Manual operation mechanism can be installed at the top and bottom. |

| Configuration actuator | GT、AT、AW series single and double acting pneumatic actuator | 4、Rack connection adjustable opening Angle, rated flow. |

| Control mode | Two position switch control, 4-20mA analog control | 5、Actuator optional live signal feedback indication and accessories to achieve automatic operation. |

Third, pneumatic fluorine lined ball valve main technical parameters and performance

| Design and manufacture | GB/T 12237 |

| Flange size | HG/T 20592 |

| Structural length | GB/T 12221 |

| Inspection and test | GB/T 13927 |

Fourth, pneumatic lined fluorine ball valve main parts materials

| Part name | material |

| Valve body, bonnet | WCB+F46 | 304(CF8)+F46 | 316(CF8M)+F46 | 316L(CF3M)+F46 |

| sphere | Carbon steel+F46/PFA | 304+F46/PFA | 316+F46/PFA | 316L+F46/PFA |

| Valve stem | Carbon steel+F46/PFA | 304+F46/PFA | 316+F46/PFA | 316L+F46/PFA |

| Seat ring | PTFE |

| Sealing packing | V-type PTFE filler |

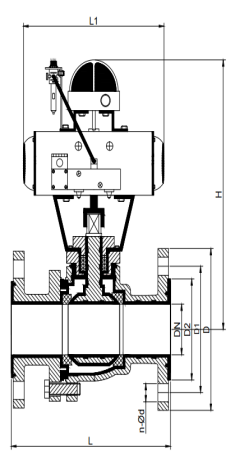

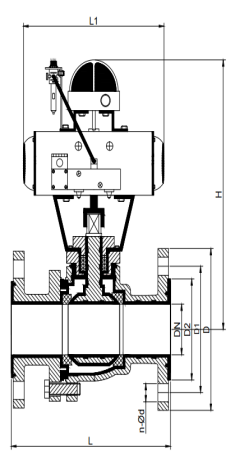

Fifth, pneumatic ball valve lined with fluorine main shape connection size:

| Nominal diameter DN(mm) | Main size | Flange size |

| PN1.6MPa | PN2.5MPa |

| L | H | L1 | D | D1 | D2 | n-φd | D | D1 | D2 | n-φd |

| 15 | 130 | 185 | 140 | 95 | 65 | 46 | 4-14 | 95 | 65 | 46 | 4-14 |

| 20 | 140 | 191 | 140 | 105 | 75 | 45 | 4-14 | 105 | 75 | 56 | 4-14 |

| 25 | 150 | 193 | 140 | 115 | 85 | 65 | 4-14 | 115 | 85 | 65 | 4-14 |

| 32 | 165 | 212 | 164 | 140 | 100 | 76 | 4-18 | 140 | 100 | 76 | 4-18 |

| 40 | 180 | 217 | 164 | 150 | 110 | 84 | 4-18 | 150 | 110 | 84 | 4-18 |

| 50 | 200 | 260 | 190 | 165 | 125 | 99 | 4-18 | 165 | 125 | 99 | 4-18 |

| 65 | 220 | 293 | 210 | 185 | 145 | 118 | 4-18 | 185 | 145 | 118 | 8-18 |

| 80 | 250 | 323 | 247 | 200 | 160 | 132 | 8-18 | 200 | 160 | 132 | 8-18 |

| 100 | 280 | 382 | 276 | 220 | 180 | 156 | 8-18 | 235 | 190 | 156 | 8-22 |

| 125 | 320 | 468 | 348 | 250 | 210 | 184 | 8-18 | 270 | 220 | 184 | 8-26 |

| 150 | 360 | 510 | 378 | 285 | 240 | 211 | 8-22 | 300 | 250 | 211 | 8-26 |

| 200 | 400 | 655 | 524 | 340 | 295 | 266 | 12-22 | 360 | 310 | 274 | 12-26 |

| 250 | 630 | / | / | 405 | 355 | 319 | 12-26 | 425 | 370 | 330 | 12-30 |

| 300 | 750 | / | / | 460 | 410 | 370 | 12-26 | 485 | 430 | 389 | 16-30 |

Note: The above size is for reference only, the specific size is based on physical objects.

Notice to quotation:

1, valve body parameters: caliber, working pressure, valve body material, using medium, connection form and other parameters

2, actuator: actuator form, control mode, control signal (4-20MA), mode of action (gas-open gas-close type)

3, optional accessories: solenoid valve, limit switch, two couplings

Please try to provide details about the American standard pneumatic ball valve parameters, to facilitate our technical personnel for your accurate selection.

Flange size