Product introduction introduction

※ Product name:Fluorine lined tee

※Flange standard:HG/T 20592

※ Nominal pressure:PN10 PN16 CL150

※ Lining standard:HG /T 20538-2016

※ Lining material:PTFE、FEP(F46)、PFA、PO

※ Non-standard parts can be specially processed according to drawings

First、Product overview

Fluorine lined tee should mainly be used in the branch of the pipeline, the interface of the instrument, discharge port and other places. After years of practical use of fluorine-lined pipe fittings and pipes, the factors that directly affect their service life and stable performance are temperature, pressure, medium and so on. High quality materials and advanced manufacturing process are the guarantee of the quality of PTFE lining products. A good PTFE resin is selected through reasonable formula, and the fluorine plastic is hot fused with the steel tube matrix by integral molding. Make the whole fluorine-lined pipe fittings have the following characteristics:

1、High use temperature: under the condition of strong corrosive medium, can meet the use of temperature range -60℃ ~ 200℃, in this temperature range (in addition to molten alkali metals, elemental fluorine and aromatic hydrocarbons), can meet all chemical media.

2、Vacuum resistance: In the range of -60℃ ~ 150℃, can be used in vacuum conditions, in chemical production, often due to cooling, longitudinal discharge, pump valve asynchronous operation of the local vacuum state.

3、High pressure resistance: In the range of temperature, can withstand up to 3Mpa operating pressure.

4、Permeability resistance: The selection of high quality resin, through advanced lining technology processing into high density, enough thickness of PTFE lining layer, so that the product has superior permeability resistance.

5、The integral molding sintering process has solved the problem of hot and cold expansion of fluorine lining, so that it can achieve synchronous expansion.

6、Adopt the standardized size preparation, especially the chemical pipeline used in the pipeline, pipe fittings have a strong interchangeability, for the installation, spare parts to provide great convenience.

Second、 Test and inspection of PTFE lining layer

1、 The pipe and pipe fittings are tested by hydraulic pressure at 1.5 times the design pressure

2、Where the PTFE lining layer is involved in the water pressure test,100% of the integrity test is carried out, and the leakage point test method is electric spark test.

Third、Maintenance and precautions before use

1、 Shall not be stored in the open air for a long time, avoid the sun, rain, avoid violent collision, multi-layer stacking heavy pile pressure.

2、 The sealing surface is not allowed to scrape, cut, scratch, scratch or collide with hard objects.

3、 It is not allowed to weld, wind cut, fire roast on the steel body of pipe fittings and fittings after lining, and it should be more than 1 meter apart from the heat source.

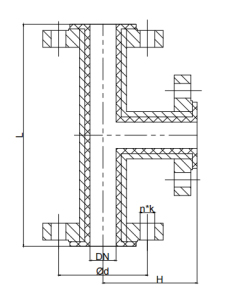

Product parameter

Main connection size

unit:mm

Nominal diameterDN | length

L | height

H | Flange spacingФd | Screw holen*k |

0.6MPa | 1.0MPa | 1.6MPa | 0.6MPa | 1.0MPa | 1.6MPa |

25 | 180 | 90 | 75 | 85 | 85 | 4-Ф11 | 4-Ф14 | 4-Ф14 |

32 | 200 | 100 | 90 | 100 | 100 | 4-Ф14 | 4-Ф18 | 4-Ф18 |

40 | 220 | 110 | 100 | 110 | 110 | 4-Ф14 | 4-Ф18 | 4-Ф18 |

50 | 240 | 120 | 110 | 125 | 125 | 4-Ф14 | 4-Ф18 | 4-Ф18 |

65 | 260 | 130 | 130 | 145 | 145 | 4-Ф14 | 8-Ф18 | 8-Ф18 |

80 | 280 | 140 | 150 | 160 | 160 | 4-Ф18 | 8-Ф18 | 8-Ф18 |

100 | 300 | 150 | 170 | 180 | 180 | 4-Ф18 | 8-Ф18 | 8-Ф18 |

125 | 320 | 160 | 200 | 210 | 210 | 8-Ф18 | 8-Ф18 | 8-Ф18 |

150 | 400 | 200 | 225 | 240 | 240 | 8-Ф18 | 8-Ф22 | 8-Ф22 |

200 | 450 | 225 | 280 | 295 | 295 | 8-Ф18 | 8-Ф22 | 12-Ф22 |

250 | 500 | 250 | 335 | 350 | 355 | 12-Ф18 | 12-Ф22 | 12-Ф26 |

300 | 560 | 280 | 395 | 400 | 410 | 12-Ф22 | 12-Ф22 | 12-Ф26 |

350 | 600 | 300 | 445 | 460 | 470 | 12-Ф22 | 16-Ф22 | 16-Ф26 |

400 | 650 | 325 | 495 | 515 | 525 | 16-Ф22 | 16-Ф26 | 16-Ф30 |