Product introduction

※ Product name:Fluorine-lined pipe

※ Flange standard:HG/T 20592

※ Nominal pressure:PN10 PN16 CL150

※ Lining standard:HG /T 20538-2016

※ Inspection standard:HG/T 2437-2006

※ Lining material:Tetrafluoroethylene PTFE、polyolefinPO、polyethylenePE、polypropylenePP

First、Product overview

According to the material is divided into PO lined pipes and accessories and PTFE lined pipes and accessories, PTFE lined pipes and accessories according to the production process is divided into winding process, molding process, loose lining process. The pipe produced by molding and winding process can withstand certain negative pressure in the piping system.

1、PTFE loose lined straight pipe and pipe fittings

PTFE lined straight pipe and pipe fittings, also known as loose liner fittings, it is used in the pipeline without negative pressure working conditions, its process for the use of PTFE powder machine production into PTFE pipe, and then the PTFE tube blank lining has been welded into the seamless steel pipe parts. Suitable for normal pressure, positive pressure pipeline.

Diameter specification:DN25~300mm;

Operating temperature:-50~120℃;

Working pressure:1.6MPa.

2、PTFE molded straight pipe and pipe fittings

PTFE molded straight pipe and pipe fittings, also known as molded pipe fittings, it is used under the working conditions of negative pressure in the pipeline, its process using PTFE powder has been made according to the requirements of the seamless steel pipe, pipe fittings in high pressure finalize, finalize in high temperature furnace for high temperature sintering forming.

Diameter specification:DN25~300mm;

Operating temperature:-50~180℃;

Working pressure:-0.09~1.6MPa.

3、PTFE Wound straight pipe

The first several layers of PTFE film wound on the mold, and then the steel wire (0.5-1mm) spiral wound on the PTFE film, after the steel wire outside and then wound several layers of PTFE thin, finally placed in the furnace wound form. The PTFE lined tube made by this process has a smooth inner wall, and the outer wall forms a spiral ripple due to the volume of the steel wire and its external elastic force. It is lined into the steel parts, and the gap between the outer wall of the PTFE lining equipment and the inner wall of the steel pipe is filled with filling resin (non-residual air). This filling resin binds tightly to the steel pipe. At the same time, it can be tightly wrapped on the outer wall of the helical PTFE lining equipment. When the filling resin cures, it forms spiral ripples that interlock with the outer wall ripples of the lining. This structure is similar to the combination of nut and bolt. On the one hand, the thermal expansion and cold contraction of PTFE lining can be effectively limited and compensated. On the other hand, the negative pressure resistance of PTFE lining is improved obviously by using the stiffness of steel wire.

Diameter specification:DN25~300mm;

Operating temperature:-50~180℃;

Working pressure:-0.06~1.6MPa.

Second、 Test and inspection of PTFE lining layer

1、 The pipe and pipe fittings are tested by hydraulic pressure at 1.5 times the design pressure

2、 Where the PTFE lining layer is involved in the water pressure test,100% of the integrity test is carried out, and the leakage point test method is electric spark test.

Third、Maintenance and precautions before use

1、 Shall not be stored in the open air for a long time, avoid the sun, rain, avoid violent collision, multi-layer stacking heavy pile pressure.

2、 The sealing surface is not allowed to scrape, cut, scratch, scratch or collide with hard objects.

3、 It is not allowed to weld, wind cut, fire roast on the steel body of pipe fittings and fittings after lining, and it should be more than 1 meter apart from the heat source.

Product parameter

First、Main connection size

Fluorine-lined drain ring is mainly used for installation of pipeline instruments or liquid drain. Different lining materials can be selected according to the working conditions. The highest temperature resistance is 180℃. After the lining can withstand various concentrations of aqua royalty, sulfuric acid, hydrochloric acid, and various organic acids, strong acids, strong oxidants and other media.

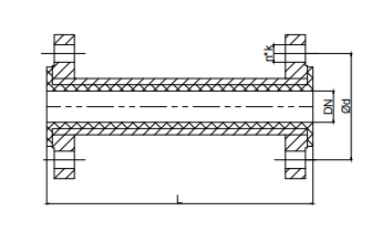

Second、Main connection size

unit:mm

Nominal diameter | Maximum length of steel tube with different lining materials | Flange spacingФd | Screw holen*k |

DN(mm) | NPS

(inch) | Loose linerL | Molded pipeL | Wound pipeL | 0.6MPa | 1.0MPa | 1.6MPa | 0.6MPa | 1.0MPa | 1.6MPa |

15 | 1/2 | | | | | | | | | |

20 | 3/4 | 4000 | 2000 | | 75 | 85 | 85 | 4-Ф11 | 4-Ф14 | 4-Ф14 |

25 | 1 | 4000 | 2000 | | 90 | 100 | 100 | 4-Ф14 | 4-Ф18 | 4-Ф18 |

32 | 11/4 | 4000 | 2000 | | 100 | 110 | 110 | 4-Ф14 | 4-Ф18 | 4-Ф18 |

40 | 11/2 | 4000 | 2000 | | 110 | 125 | 125 | 4-Ф14 | 4-Ф18 | 4-Ф18 |

50 | 2 | 4000 | 2000 | 2000 | 130 | 145 | 145 | 4-Ф14 | 8-Ф18 | 8-Ф18 |

65 | 21/2 | 4000 | 2000 | 2000 | 150 | 160 | 160 | 4-Ф18 | 8-Ф18 | 8-Ф18 |

80 | 3 | 4000 | 2000 | 2000 | 170 | 180 | 180 | 4-Ф18 | 8-Ф18 | 8-Ф18 |

100 | 4 | 3000 | 2000 | 2000 | 200 | 210 | 210 | 8-Ф18 | 8-Ф18 | 8-Ф18 |

125 | 5 | 3000 | 2000 | 2000 | 225 | 240 | 240 | 8-Ф18 | 8-Ф22 | 8-Ф22 |

150 | 6 | 2000 | 2000 | 1500 | 280 | 295 | 295 | 8-Ф18 | 8-Ф22 | 12-Ф22 |

200 | 8 | 2000 | 2000 | 1500 | 335 | 350 | 355 | 12-Ф18 | 12-Ф22 | 12-Ф26 |

250 | 10 | 2000 | 1500 | 1500 | 395 | 400 | 410 | 12-Ф22 | 12-Ф22 | 12-Ф26 |

300 | 12 | 2000 | 1500 | 1000 | 445 | 460 | 470 | 12-Ф22 | 16-Ф22 | 16-Ф26 |

400 | 16 | 2000 | 1500 | 1000 | 495 | 515 | 525 | 16-Ф22 | 16-Ф26 | 16-Ф30 |

note:According to the design requirements, negotiate with the supplier to choose other lengths of steel pipe.

Third、Order specification

1、Conditions of use, such as temperature, pressure

2、Lining material, lining plastic, lining fluorine

3、Flange standards and grades