Product introduction

※ Product name:Fluorine lined metal hose

※ Product model:JTW41F46-16P/C

※ Product specification:DN25-300

※ Lining material:PTFE

※ Connection mode: flange, thread buckle

※ Working pressure:≤0.6Mpa

First, product characteristics

PTFE corrugated hose through a special processing method, changed the characteristics of the previous pipe can not bend, it can be connected to the mechanical strength of low graphite, ceramic or glass pipe, can be used for tank car, storage tank, container or reactor feed, discharge pipe, pipe dislocation connection, for climate and other reasons caused by the pipeline displacement, Changes in site size may be used to eliminate high-frequency mechanical vibration. In special occasions, it can also be used as a tubular reactor or heat exchanger. In addition, it can also be used as shielding cables for aircraft engines and flexible insulation sleeves to protect cables or conductors.

Corrugated hose can provide DN10~DN300 caliber, 20cm-20m length, its wall thickness standard is 1.5 mm ~3.5 mm, fatigue times ≥10000 (room temperature)

Second, PTFE hose type

1. Ordinary PTFE hose

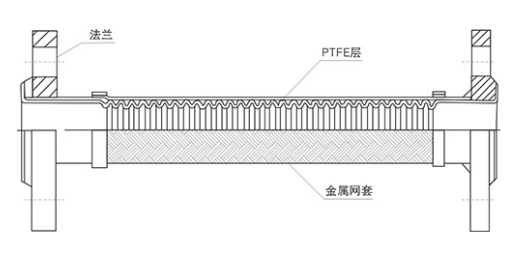

2, stainless steel mesh composite hose

PTFE metal mesh sleeve threaded hose, it is in the PTFE thread hose woven a layer or multiple layers of wire mesh or rigid belt sleeve (depending on the pressure), both ends of the joint or flange of the flexible element. It can absorb vibration, compensate displacement, especially in the pipeline system has the ability to compensate large displacement.

3, PTFE hose performance

Strong corrosion resistance, vibration absorption, displacement compensation, especially in the pipeline system has large compensation, large displacement capacity, at the same time with light weight, small volume, fatigue resistance, flexibility and so on.

Third, the structure of PTFE hose

Fourth, the implementation of standards

1, according to the manufacturing standard GB/T 14525-93 "corrugated metal hose general technical conditions".

2. Flanges are flat welded flanges, flange standard GB/T9119-2000, can also be selected according to the requirements of the demander, flange sealing surface size shall be manufactured according to the size of sealing surface specified in the selection standard.

3, bellows shell material selection: carbon steel, 304, 316, 316L.

4, lining material selection: PTFE.

5, the use of steel lined tetrafluoroidal metal hose temperature: -50℃ ~ 150℃; The working pressure of steel lined tetrafluorometal hose is -0.09Mpa ~ 2.5Mpa(depending on the working temperature and pipe diameter).

6, can resist the penetration of small molecular gases, including oxygen, carbon dioxide, chlorine gas, hydrogen chloride gas.

7, high purity, very low precipitation rate, in line with the purity requirements of the photovoltaic industry.

8, the surface is very smooth, the friction coefficient is very small. Strong mechanical properties, strong, good wear resistance.

Product parameter

First, lined with tetrafluoroidal metal hose installation operation requirements

1. Installation

Hoses should not be twisted or used when installing or using hoses should not be excessively bent or bent into a diameter less than the specified minimum bending radius. Hoses should be installed so that bending always occurs in the same plane. It is recommended that flange assemblies have a floating flange at one end of the installation easier and reduce the possibility of twisting.

2. Cleaning

Before storage, hoses should be drained and rinsed with clean water to remove dangerous vapors, such as sulfuric acid when diluted with water, which can have strong corrosive slag hoses. In this case, the drain main pipe must be grounded, and during the cleaning operation, the hose can be cleaned using a low-pressure air hose, but excessive pressure must be avoided and built open. Avoiding excessive pressure is open to building. Steam is not recommended for cleaning excessive temperatures (over 100°C) that will damage the hose fabric.

3. Processing

Hoses should be stored in solid support or rack lines. Large bore hoses should be carried on a small bollard or elongated. The hose must not be supported by a single cord or brace. Wide belt spreader should use matching hose at least every 3 meters. Avoid curvature less than the minimum bend radius of the hose.

Do not let sharp hands near the end of the connection fit the area in the weakest part of any type of hose.

Hoses should not be dragged along the ground or guardrail. Do not allow the hose to rub (rub) against hard surfaces and/or sharp edges. If unavoidable, consider hoses with wire ropes.

4. Check

Inspect at least the visual damage hose every six months

Observe:

(1) The adjacent end joint of the hose is weakened

(2) Cuts and abrasions on the fabric surface

(3) Outer steel wire wear

(4) Determine the outer displacement by the length between the lines of each wheel with different widths

(5) Dents, knotted or twisted parts

5. Test

Composite hose assemblies shall be hydraulically tested at least every twelve (12) months and electrical continuity tested at least every six (6) months if applicable.

Second, precautions for installation of steel lined tetrafluoroidal metal hose

1. The installation of steel lined tetrafluoroidal metal hose shall be carried out in accordance with the requirements of pipe system construction drawings and metal hose installation instructions.

2, steel lined with four fluorine metal hose corrugated pipe is made of thin-wall stainless steel plate and polytetrafluoroethylene molding, so during transportation, lifting and welding should pay attention not to knock, scratch, arc, welding splash and other reasons to damage the corrugated pipe.

3. Before installation, the steel lined tetrafluorometal hose and foreign bodies in the pipe should be removed to ensure the normal movement of the bellows.

4. In order to make the steel lined tetrafluoroethylene metal hose in good working condition, the deformation of the steel lined tetrafluoroethylene metal hose, including axial, transverse and torsion, can not be used to adjust the installation error of the piping position.

Third, order instructions

1, steel lined PTFE metal hose working environment is normal temperature and pressure, can choose wire lined fluorine hose.

2, steel lined metal tetrafluoroethylene hose working environment pressure ≥0.6Mpa, choose steel lined metal tetrafluoroethylene hose

Please specify the order and write it into the purchase contract.